Labo abasebenzise aumshini wokuthungayazini ukuthi i-beveling machine blade idlala indima ebalulekile ekusikeni nasekufakeni amashidi ensimbi namapayipi. I-blade ingadala ngokunembile nangempumelelo i-bevel oyifunayo lapho i-beveling amashidi noma amapayipi. Namuhla sizoxoxa ngokuthi yiziphi izici okufanele zicatshangelwe ekukhetheni ama-beveling machine blades.

umshini wensimbi onqenqemeni lwe-bevelingama-blades aklanyelwe ukuhlangabezana nezidingo ezithile zenqubo yokusika. Idizayinelwe ukumelana nobunzima bokusika izinto eziqinile kuyilapho igcina ukucijile nokuqina. Ikhwalithi ye-blade ithinta ngokuqondile ikhwalithi ye-bevel, iyenze ibe isici esibalulekile ekuzuzeni ukusikeka okunembile, okuhlanzekile.

Esinye sezici eziyinhloko ze-blade yi-bevel yayo, enquma i-engeli lapho impahla isikwa khona. Izinto ezihlukile zingadinga ama-engeli ahlukene we-bevel, futhi i-blade kufanele ikwazi ukuthwala lezi zinguquko. Ukwengeza, ukucija kwe-blade kubalulekile ukuze ufinyelele ukusika okuhlanzekile ngaphandle kokulimaza impahla ecutshungulwayo.

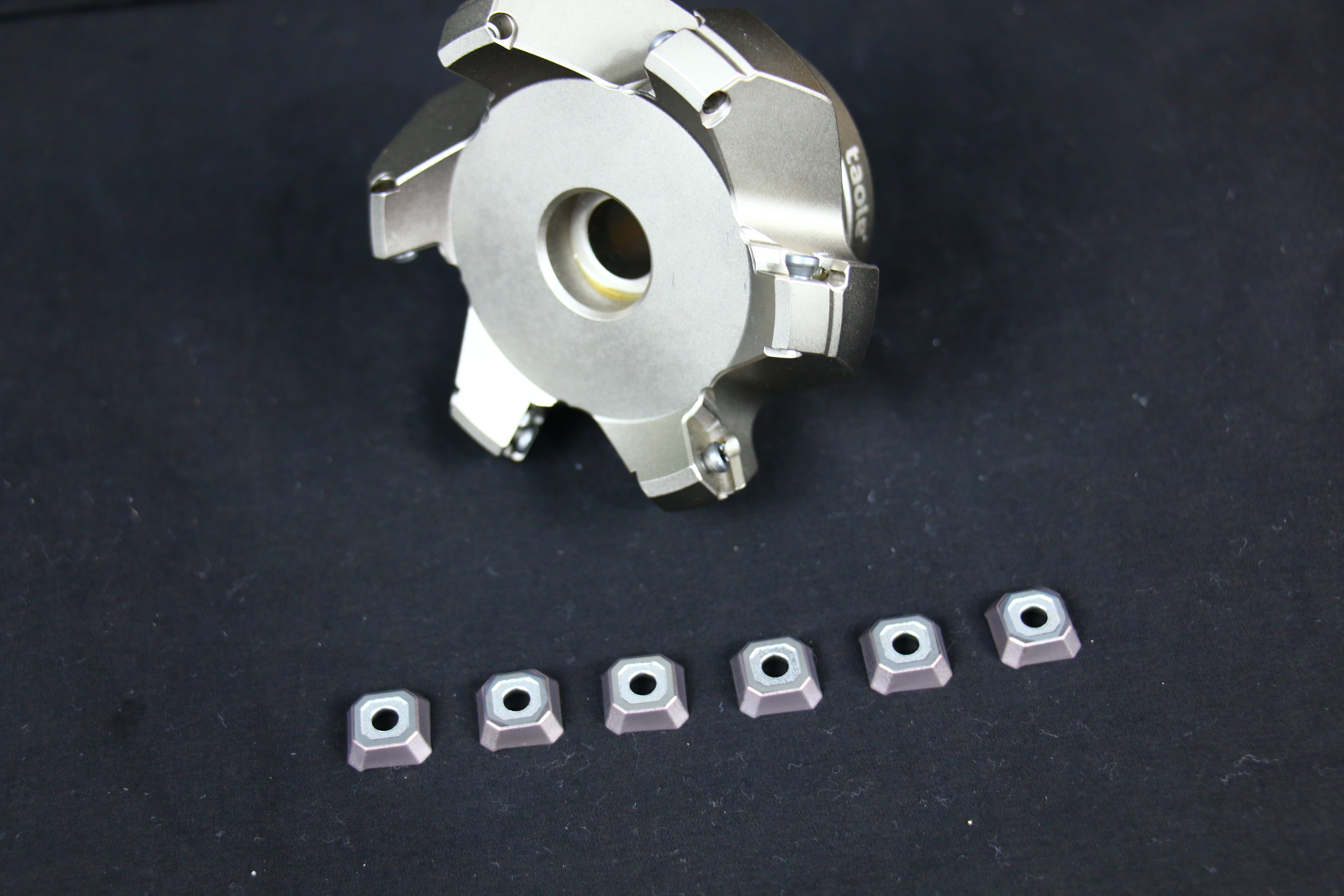

Impahla ye-blade nayo idlala indima ebalulekile ekusebenzeni kwayo. Ama-blade ekhwalithi ephezulu ngokuvamile enziwa ngezinto ezihlala isikhathi eside njengensimbi enesivinini esikhulu, i-carbide, noma idayimane, aziwa ngobulukhuni nokungagugi. Lezi zinto ziqinisekisa ukuthi ama-blades agcina ukucija kwawo kanye nokusebenza kahle kokusika phakathi nesikhathi eside sokusetshenziswa.

Izinto ezisetshenziselwa ukucubungula amashidi ensimbi kuwukucatshangelwa okubalulekile. Izinto ezihlukene zamashidi ensimbi zinobunzima obuhlukene kanye nezakhiwo zokusika, ngakho-ke kubalulekile ukukhetha i-groove blade ehambisanayo.

Kumashidi ensimbi aqinile, njengensimbi engagqwali kanye nensimbi ye-alloy, ubulukhuni bawo buphakeme, okungaholela kalula ekwandeni kokugqoka kwamathuluzi. Lapho ucubungula lezi zinto, kunconywa ukuthi ukhethe amathuluzi okusika anokumelana okuhle kokugqoka, ngokuvamile lawo anokwelashwa kokumboza phezulu. Lezi zembatho zinganikeza ukusebenza okungcono kokusika futhi zandise impilo yamathuluzi.

Kumashidi ensimbi athambile, njenge-carbon steel, ubulukhuni bawo buphansi futhi izidingo zamathuluzi okusika ziphansi. Ngakho-ke, amathuluzi avamile okusika insimbi ngokuvamile angahlangabezana nezidingo zokucubungula.

Khetha umumo wokusika kanye nosayizi we-blade ngokusekelwe ekubunjweni nobukhulu be-groove. Izimo ezivamile ze-groove zihlanganisa okumise okwe-V, okumise u-U, kanye no-J ukuze kuqinisekiswe ukuthi i-blade ingahlinzeka ngesimo se-groove oyifunayo.

Izindwani zekhwalithi ephezulu ezingashintshwa zinikeza umumo odingekayo we-groove.

Ukuze uthole olunye ulwazi oluthakazelisayo noma olwengeziwe oludingekayo mayelanaUmshini wokugaya we-Edge and Edge Beveler. please consult phone/whatsapp +8618717764772 email: commercial@taole.com.cn

Isikhathi sokuthumela: Apr-29-2024