Ukwakhiwa kwemikhumbi kuyinkambu eyinkimbinkimbi futhi enenkani lapho inqubo yokukhiqiza idinga ukunemba futhi isebenze kahle.Imishini yokugaya i-Edgeangelinye lamathuluzi abalulekile aletha izinguquko kulo mkhakha. Lo mshini othuthukisiwe udlala indima ebalulekile ekubumbeni nasekuqedeni imiphetho yezingxenye ezihlukahlukene ezisetshenziswa ekwakhiweni komkhumbi, ukuqinisekisa ukuthi zihlangabezana nezindinganiso eziqinile zekhwalithi ezidingekayo ekusetshenzisweni kwasolwandle.

Namuhla, ngithanda ukwethula inkampani yokwakha nokulungisa umkhumbi esiFundazweni saseZhejiang. Isebenza kakhulu ekukhiqizeni ujantshi, ukwakha imikhumbi, i-aerospace, nezinye izinto zokuhamba.

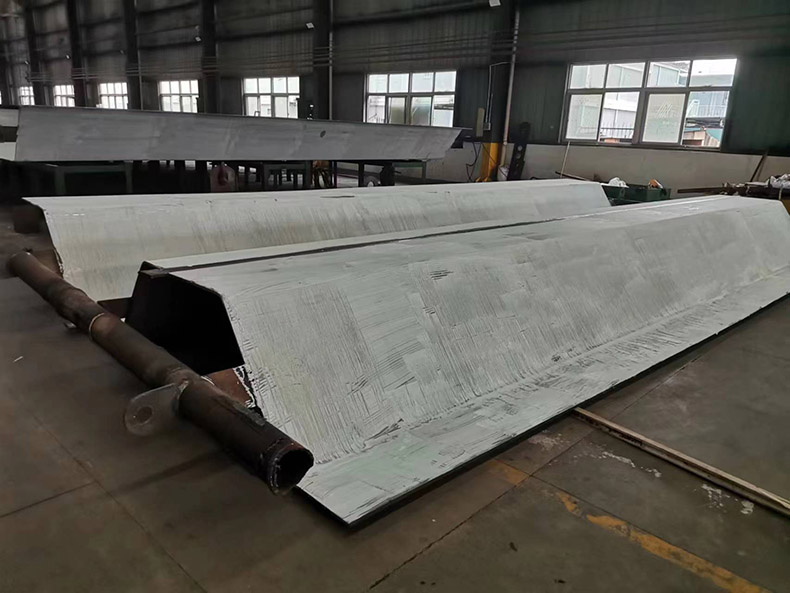

Ikhasimende lidinga ukucutshungulwa esizeni kwezinto zokusebenza ze-UNS S32205 7 * 2000 * 9550 (RZ), Ikakhulukazi ezisetshenziselwa izindawo zokugcina izimpahla zikawoyela, igesi kanye nemikhumbi yamakhemikhali, izidingo zazo zokucutshungulwa ziyimifantu emise okwe-V, futhi imifantu emise okwe-X idinga ukucutshungulwa ukuze ifinyelele ubukhulu obuphakathi kuka-12-16mm.

Sincoma umshini wokugcwalisa amapuleti we-GMMA-80R kumakhasimende ethu futhi senze izinguquko ezithile ngokuya ngezidingo zenqubo.

Umshini we-GMM-80R obuyiseleka emuva we-beveling weshidi lensimbi ungacubungula i-V/Y groove, i-X/K groove, kanye nemisebenzi yokugaya i-plasma yensimbi engenasici.

Imingcele yomkhiqizo

| PRODUCT MODEL | I-GMMA-80R | Icubungula ubude bebhodi | > 300 mm |

| Pukunikezwa kwamandla | I-AC 380V 50HZ | Beveli-angle | 0°~±60°Iyalungiseka |

| Tamandla otal | 4800w | Awushadilei-bevelububanzi | 0 ~ 20mm |

| Isivinini se-spindle | 750~1050r/min | Bevelububanzi | 0 ~ 70mm |

| Isivinini Sokuphakelayo | 0~1500mm/min | Ububanzi be-blade | φ80mm |

| Ubukhulu be-clamping plate | 6-80 mm | Inani lama-blades | 6pcs |

| Ububanzi bepuleti lokubamba | > 100mm | Ukuphakama kwebhentshi | 700*760mm |

| Gisisindo serosi | 385kg | Usayizi wephakheji | 1200*750*1300mm |

Isibonisi senqubo yokucubungula:

Imodeli esetshenzisiwe i-GMM-80R (umshini wokugaya onqenqemeni ozenzakalelayo), okhiqiza ama-grooves ngokuhambisana okuhle nokusebenza kahle okuphezulu. Ikakhulukazi uma wenza imisele emise okuka-X, asikho isidingo sokuphenyisisa ipuleti, futhi ikhanda lomshini lingaphetshwa ukuze lenze umqansa, konga kakhulu isikhathi sokuphakamisa nokuphenyisisa ipuleti. Umshini wokuntanta wekhanda lomshini owenziwe ngokuzimela ungaphinda uxazulule ngempumelelo inkinga yemisele engalingani ebangelwa amagagasi angalingani endaweni yepuleti.

Isibonisi somphumela we-Welding:

Isikhathi sokuthumela: Dec-16-2024