Kaho ea likepe ke tšimo e rarahaneng le e hlokang boiteko bo bongata moo ts'ebetso ea tlhahiso e hlokang ho nepahala le ho sebetsa hantle.Mechini ea ho sila ea Edgeke e 'ngoe ea lisebelisoa tsa bohlokoa tse fetolang indasteri ena. Mochini ona o tsoetseng pele o bapala karolo ea bohlokoa ho bopeng le ho phetheleng mathoko a likarolo tse fapaneng tse sebelisoang kahong ea likepe, ho netefatsa hore li fihlela maemo a thata a boleng a hlokahalang bakeng sa lits'ebetso tsa likepe tsa metsing.

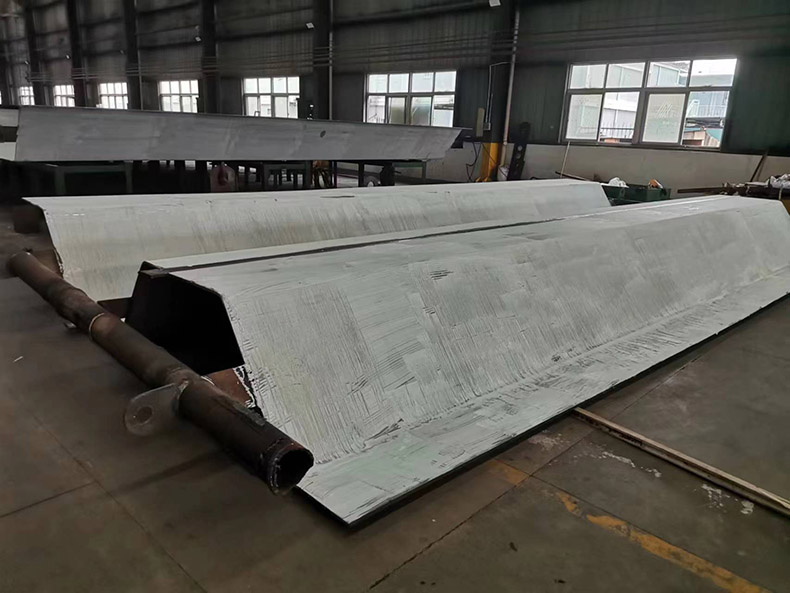

Kajeno, ke rata ho hlahisa khamphani ea kaho le tokiso ea likepe e Profinseng ea Zhejiang. E sebetsana haholo le tlhahiso ea literene, kaho ea likepe, lifofane le lisebelisoa tse ling tsa lipalangoang.

Moreki o hloka ts'ebetso ea libaka tsa mosebetsi tsa UNS S32205 7 * 2000 * 9550 (RZ) sebakeng seo, Tse sebelisoang haholo bakeng sa polokelo ea likepe tsa oli, khase le lik'hemik'hale, litlhoko tsa ts'ebetso ea tsona ke li-groove tse bōpehileng joaloka V, 'me li-groove tse bōpehileng joaloka X li hloka ho sebetsoa bakeng sa botenya bo pakeng tsa 12-16mm.

Re khothaletsa mochini oa ho bevel oa poleiti ea GMMA-80R ho bareki ba rona 'me re entse liphetoho tse ling ho latela litlhoko tsa ts'ebetso.

Mochini oa ho betla o ka fetoloang oa GMM-80R bakeng sa lakane ea tšepe o ka sebetsana le moqomo oa V/Y, moqomo oa X/K, le ts'ebetso ea ho sila ea tšepe e sa hloekang ea plasma.

Liparamente tsa sehlahisoa

| MOETSI OA SEHLAHISOA | GMMA-80R | Bolelele ba boto ea ho e sebetsana | >300mm |

| Pphepelo ea matla | AC 380V 50HZ | Bevelsekhutlo | 0°~±60°E ka fetoloa |

| Tmatla a maholo | 4800w | E le 'Ngoebevelbophara | 0 ~ 20mm |

| Lebelo la lehoakhoa | 750~1050r/motsotso | Bevelbophara | 0~70mm |

| Lebelo la Phepo | 0~1500mm/motsotso | Bophara ba lehare | φ80mm |

| Botenya ba poleiti ea ho clamping | 6 ~ 80mm | Palo ea mahare | 6pcs |

| Bophara ba poleiti ea ho tlama | >100mm | Bolelele ba benche ea mosebetsi | 700*760mm |

| Gboima ba ross | 385kg | Boholo ba sephutheloana | 1200*750*1300mm |

Pontšo ea ts'ebetso ea ts'ebetso:

Mohlala o sebediswang ke GMM-80R (mochini o tsamayang ka boiketsetso wa ho sila), o hlahisang di-groove tse nang le botsitso bo botle le bokgoni bo phahameng. Haholo-holo ha ho etswa di-groove tse bopehileng jwalo ka X, ha ho hlokahale hore ho phetlwe poleiti, mme hlooho ya mochini e ka phetlwa ho etsa leralla le theohelang, e leng se bolokang nako ya ho phahamisa le ho phetla poleiti haholo. Mokgwa o phaphametseng wa hlooho ya mochini o iketseditsweng ka boikemelo le wona o ka rarolla bothata ba di-groove tse sa lekanang tse bakwang ke maqhubu a sa lekanang hodima bokahodimo ba poleiti.

Pontšo ea phello ea ho tjheseletsa:

Nako ea poso: Tshitwe-16-2024