OEM/ODM China OCP-159 automatic cold pipe cutting beveling machine – Steel Plate Cleaning Machine

Short Description:

OEM/ODM China OCP-159 automatic cold pipe cutting beveling machine – Steel Plate Cleaning Machine Detail:

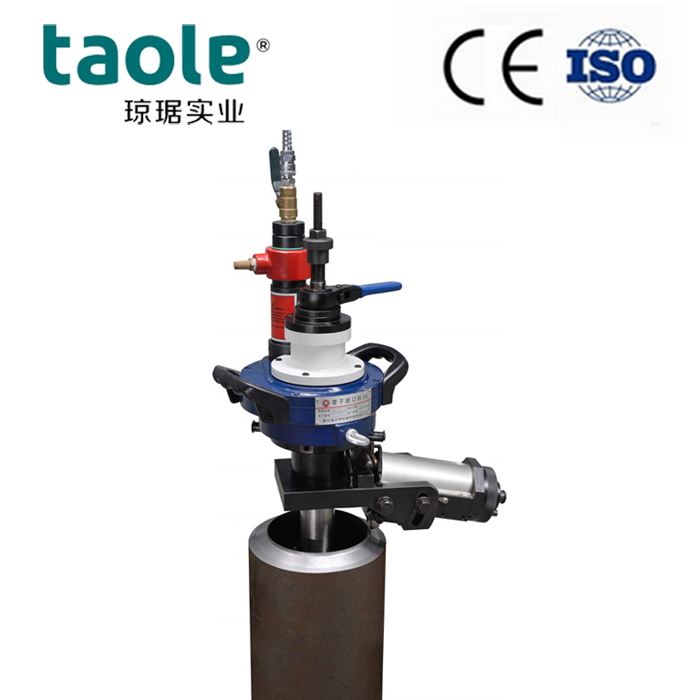

OCP-159 automatic cold pipe cutting beveling machine

Introduction

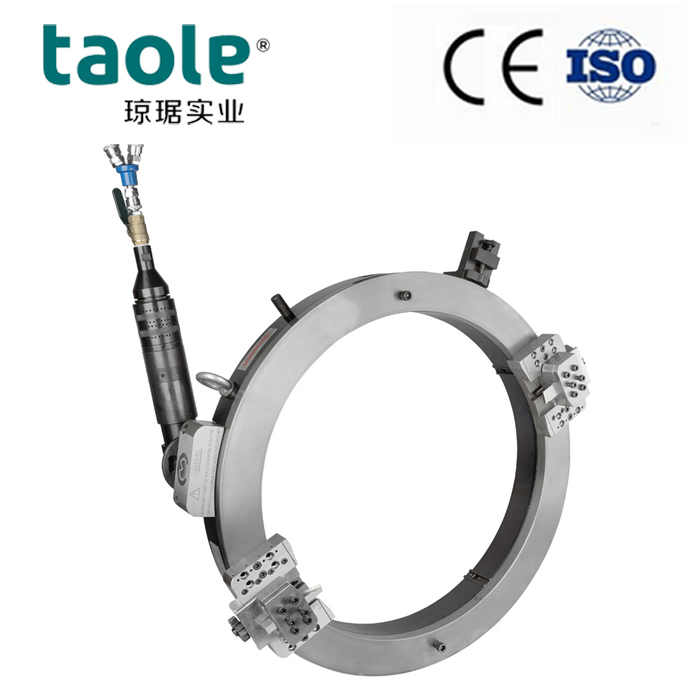

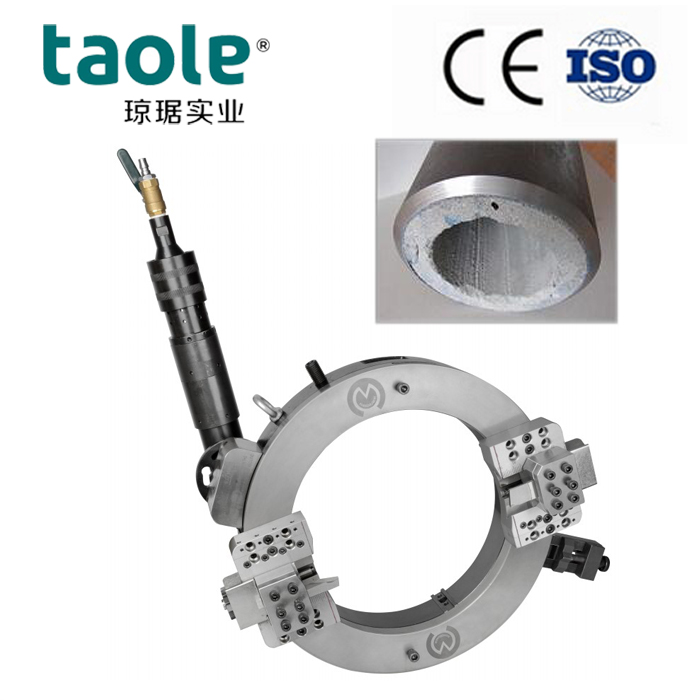

This series are portable od-mountd frame type pipe cold cutting and beveling machine with advantages of light weight, minimal radial space, easy operation and so on. Split frame design can separate mount the od of the in-lin pipe for strong and stable clamping to process cutting and beveling sumultaneously.

Specification

Power Supply: 0.6-1.0 @1500-2000L/min

| Model NO. | Working Range | Wall Thickness | Rotation Speed | Air Pressure | Air Consumption | |

| OCP-89 | φ 25-89 | 3/4‘’-3‘’ | ≤35mm | 50 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-159 | φ50-159 | 2‘’-5‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-168 | φ50-168 | 2‘’-6‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-230 | φ80-230 | 3‘’-8‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-275 | φ125-275 | 5‘’-10‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-305 | φ150-305 | 6‘’-10‘’ | ≤35mm | 18 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-325 | φ168-325 | 6‘’-12‘’ | ≤35mm | 16 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-377 | φ219-377 | 8‘’-14‘’ | ≤35mm | 13 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-426 | φ273-426 | 10‘’-16‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-457 | φ300-457 | 12‘’-18‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-508 | φ355-508 | 14‘’-20‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-560 | φ400-560 | 16‘’-22‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-610 | φ457-610 | 18‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-630 | φ480-630 | 20‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-660 | φ508-660 | 20‘’-26‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-715 | φ560-715 | 22‘’-28‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-762 | φ600-762 | 24‘’-30‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-830 | φ660-813 | 26‘’-32‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-914 | φ762-914 | 30‘’-36‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1066 | φ914-1066 | 36‘’-42‘’ | ≤35mm | 9 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1230 | φ1066-1230 | 42‘’-48‘’ | ≤35mm | 8 r/min | 0.6~1.0MPa | 2000 L/min |

Note: Standard machine packaging including : 2 pcs cutter,2pcs of bevel tool +tools + operation manual

Fetures

1. Low axial and radial clearance light weight suitable for working at narrow and complicated site

2. Split frame design can separate to 2 half, easy to process when two end not open

3. This machine can process cold cutting and beveling simultaneously

4. With option for electric, Pneuamtic, Hydraulic ,CNC based on site condition

5. Tool feed automatically with Low noise, long life and stable performance

6. Cold working without Spark , Will not affect the pipe material

7. Can process different pipe material : Carbon steel, stainless steel , alloys etc

8. Explosion Proof, Simple structure makes easy to maintenance

Bevel Surface

Application

Widely used in the fields of petroleum, chemical, natural gas,power plant construction,bolier and nuclear power, pipeline etc.

Customer Site

Packaging

Product detail pictures:

Related Product Guide:

Buying a Milling Machine – Consider Its Types and Specifications

All About Die Cutting Machines

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for OEM/ODM China OCP-159 automatic cold pipe cutting beveling machine – Steel Plate Cleaning Machine, The product will supply to all over the world, such as: Belgium, Georgia, Myanmar, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!