Laser Beveling vs. Traditional Beveling: The Future of Beveling Technology

Beveling is a key process in the manufacturing and construction industries, used to create angled edges on metal, plastic, and other materials. Traditionally, beveling is done using methods such as grinding, milling, or hand-held beveling tools. However, as technology advances, laser beveling has become a potential alternative to traditional methods. So the question is: Will laser beveling replace traditional beveling?

Laser beveling is a cutting-edge technology that uses high-powered lasers to precisely cut and shape materials, including creating beveled edges. This process offers several advantages over traditional bevel cutting methods. One of the main advantages of laser beveling is its precision and accuracy. Lasers can form bevel edges to extremely tight tolerances, ensuring a high degree of consistency and quality in the finished product. Additionally, laser beveling is a non-contact process, which means there is minimal risk of material deformation or damage during the beveling operation.

Another advantage of laser beveling is its efficiency. While traditional beveling methods often require multiple steps and tool changes to achieve the desired bevel angle, laser beveling can accomplish the same task in a single operation. Not only does this save time, it also reduces the need for manual labor, making the entire process more cost-effective.

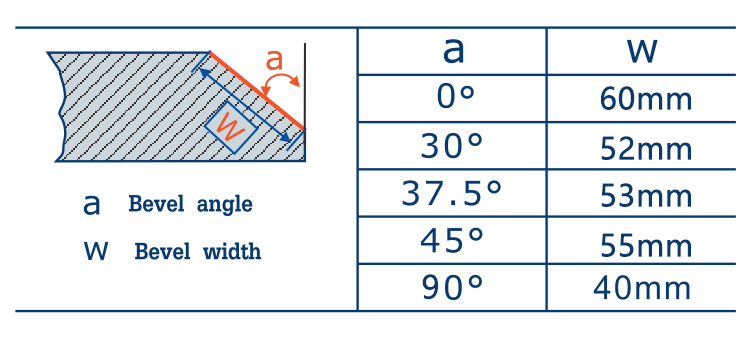

Additionally, laser beveling offers greater flexibility in terms of achievable shapes and angles. While traditional beveling tools are limited in their ability to create complex beveled designs, lasers can easily adapt to different geometries and produce precise beveled edges on a variety of materials.

Despite these advantages, it is important to consider the potential limitations of laser beveling. One of the major challenges is the initial investment required to purchase and set up laser beveling equipment. While the upfront cost of traditional beveling tools may be lower, the long-term benefits of laser beveling in terms of efficiency and quality may outweigh the initial investment.

Additionally, the expertise required to operate and maintain laser beveling equipment can be a barrier for some manufacturers. While traditional beveling methods are well recognized and understood, laser technology may require specialized training and knowledge to ensure optimal performance.

It’s also worth noting that traditional beveling methods have evolved over time, with advances in tooling and automation increasing their efficiency and accuracy. For some applications, traditional beveling methods may still be preferred, especially in industries where the cost of transitioning to laser technology may not be justified.

In summary, although laser beveling offers significant advantages in terms of accuracy, efficiency, and flexibility, it is unlikely to completely replace traditional beveling methods in the near future. Instead, the two technologies are likely to coexist, with manufacturers choosing the most appropriate approach based on their specific requirements and limitations. As laser technology continues to advance and become more readily available, its role in the beveling process is likely to expand, but traditional methods may still be suitable for some applications. Ultimately, the choice between laser beveling and conventional beveling will depend on careful consideration of the specific needs and priorities of each fabrication or construction operation.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772 email: commercial@taole.com.cn

Post time: Apr-15-2024