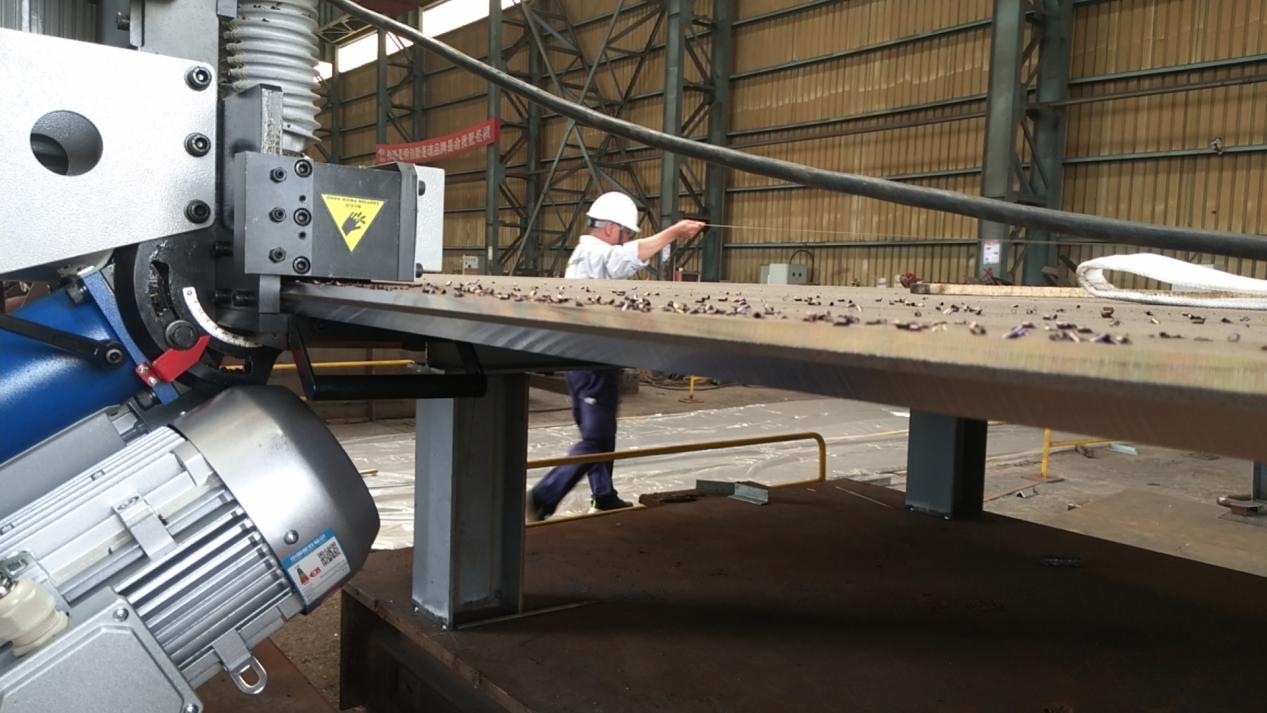

A Edge Milling Machine or we say plate edge beveler, is a edge cutting machine to make a bevel with angles or radius on edge which is common appllicated for metal beveling against weld preparation such as Shipbuilding, Metallurgy, Steel Structures, Pressure Vessels and other welding manufacturing industries.

Why comes edge milling and beveling, What is the difference?

It actually main comes different on the cutter tools and relative performance based.

GMM Edge milling machine using milling type cutter and carbide inserts.

Example:https://www.bevellingmachines.com/gmma-80a-high-efficiency-auto-walking-plate-beveling-machine.html

GBM Plate Edge Beveller using Shearing type cutter blade.

Example:Portable automatic plate beveler - China Shanghai Taole Machine https://www.bevellingmachines.com/portable-automatic-plate-beveler.html

Specification Difference between GMM Edge Milling and GBM Edge Beveler

|

Specification |

GMMA Edge milling |

GBM Edge Beveler |

|

Plate thickness |

Upto 100mm or higher |

Up 40mm |

|

Bevel Angel |

0-90 degree |

25-45 degree |

|

Bevel Width |

Upto Max 200mm |

Upto Max 28mm |

|

Electric Power |

Upto 6520W |

Upto 1500W |

|

Noise |

Approx 75db |

Approx 20 db |

|

Efficiency |

Upto 1.5 Meter |

Upto 2.5 Meter |

|

Consumables |

Milling Carbide Insert |

Cutter Blade |

|

Performance |

High Precision Ra3.2-6.3 |

Low Precision with Teeth |

|

Cost |

Option from Low to High Depends on size |

Optional with lesser option |

For further insteresting or more information required about Edge milling machine and Edge Beveler, please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Dec-08-2023