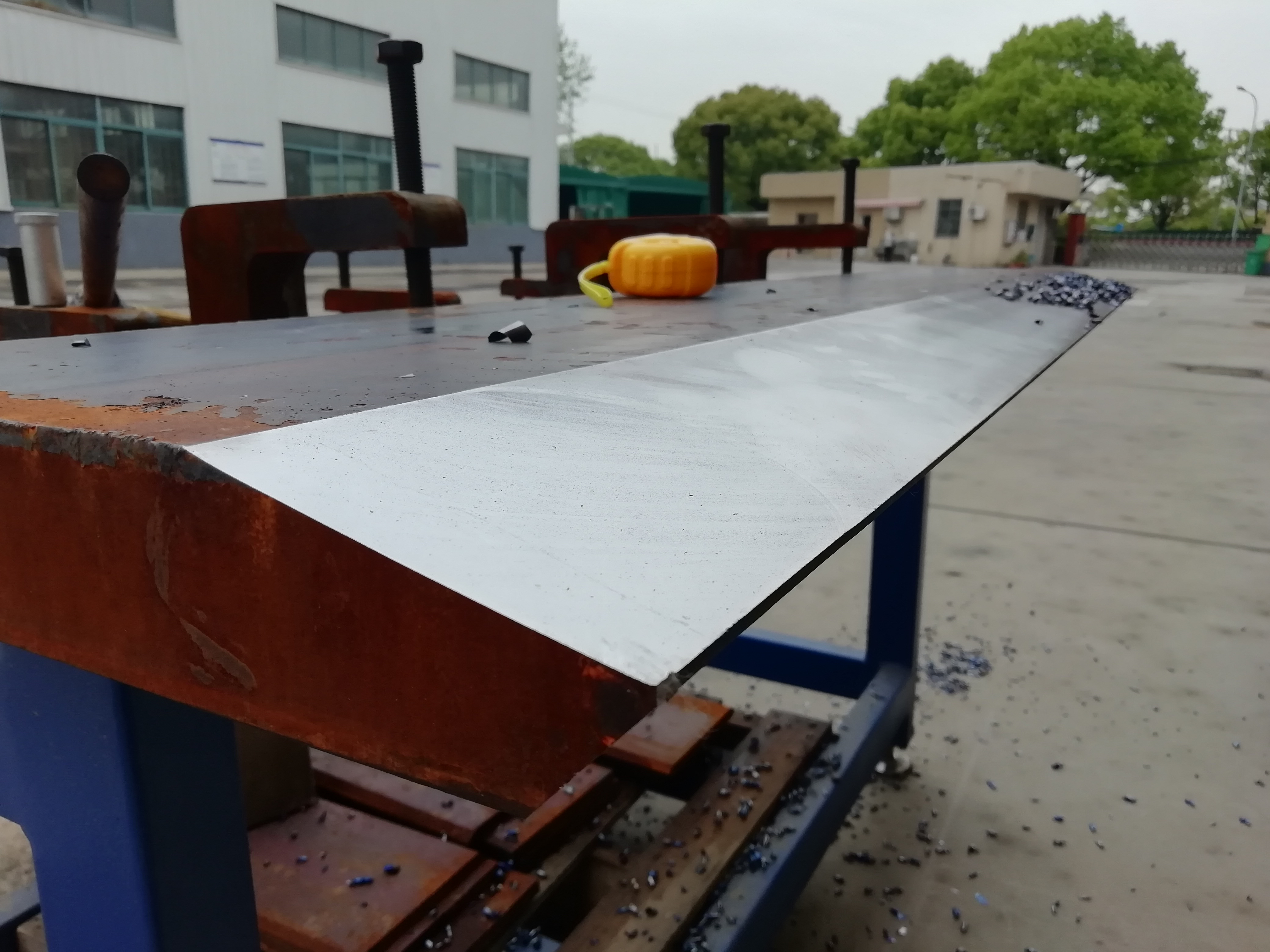

Plate beveling machines are essential tools in the metalworking industry, used to create beveled edges on metal plates and sheets. These machines are designed to efficiently and accurately bevel the edges of metal plates, providing a clean and precise finish. The process of beveling involves cutting and shaping the edge of a metal plate at an angle, typically to prepare it for welding or to improve its aesthetic appeal.

A plate beveling machine typically consists of a cutting head, a motor, and a guide system. The cutting head is equipped with a beveling tool, such as a milling cutter or a grinding wheel, which is used to remove material from the edge of the metal plate to create the desired bevel angle. The motor provides the power to drive the cutting head, while the guide system ensures that the beveling process is carried out with precision and consistency.

A plate beveling machine typically consists of a cutting head, a motor, and a guide system. The cutting head is equipped with a beveling tool, such as a milling cutter or a grinding wheel, which is used to remove material from the edge of the metal plate to create the desired bevel angle. The motor provides the power to drive the cutting head, while the guide system ensures that the beveling process is carried out with precision and consistency.

The beveling machine produced by Shanghai Taole Machinery Co., Ltd. can generate 0-90 degrees of beveling, cut the thickness of the sheet metal to 6-100mm, and can manufacture composite bevels such as U, J, K, X, etc. The beveling machine can be customized according to your requirements to meet all your needs in beveling. It can be suitable for stainless steel, carbon steel, copper, aluminum and other metal sheets. Please let me know your specific requirements, and we will provide you with professional solutions.

In addition to their functional benefits, plate beveling machines also contribute to a more professional and aesthetically pleasing finish. Beveled edges give metal plates a polished and refined appearance, making them suitable for a wide range of applications, including architectural and decorative purposes. Whether it’s for creating smooth and seamless joints in metal structures or for enhancing the visual appeal of metal components, plate beveling machines play a crucial role in achieving high-quality results.

When choosing a plate beveling machine, it’s important to consider factors such as the thickness and material of the metal plates to be processed, the required bevel angle, and the level of automation and precision needed. Additionally, factors such as portability, ease of operation, and maintenance requirements should also be taken into account.

The conventional automatic steel plate beveling machine is divided into automatic walking mechanism beveling machine and handheld automatic walking beveling machine. Compared with other beveling methods, this machine has many advantages, such as high efficiency, energy saving, environmental protection, safety, simple operation, and convenient use; And it can greatly reduce the workload of workers and save labor costs; Simultaneously in line with the current trend and concept of low-carbon and low energy consumption in environmental protection.

Safety technical regulations:

1. Before use, check whether the electrical insulation is good and the grounding is reliable. When using, wear insulated gloves, insulated shoes, or insulation pads.

2. Before cutting, check if there are any abnormalities in the rotating parts, if the lubrication is good, and perform a turning test before cutting.

When working inside the furnace, two people must collaborate and work simultaneously.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772 email: commercial@taole.com.cn

Post time: Apr-17-2024