In the ever-evolving landscape of manufacturing, the flat plate beveling machine has emerged as a crucial tool, particularly in the large-scale tube can industry. This specialized equipment is designed to create precise bevels on flat plates, which are essential for the production of high-quality tube cans. The efficiency and accuracy of these machines significantly enhance the overall manufacturing process, making them indispensable in modern production lines.

The large-scale tube can industry relies heavily on the seamless integration of various components to ensure the durability and functionality of the final product. Flat plate beveling machines play a vital role in this integration by preparing the edges of metal plates for welding. By beveling the edges, these machines facilitate better penetration of the weld, resulting in stronger joints and a more robust final product. This is particularly important in the tube can industry, where the integrity of the can is paramount to prevent leaks and maintain product freshness.

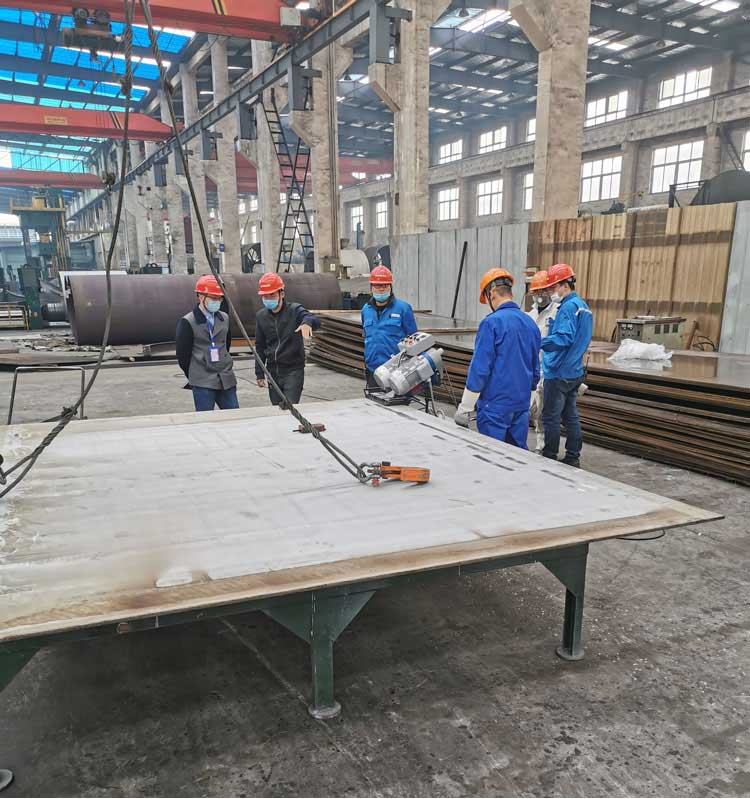

Recently, we provided services to a pipe industry company in Shanghai, which specializes in the production and sales of special materials such as stainless steel, low-temperature steel, alloy steel, duplex steel, nickel based alloys, aluminum alloys, and complete sets of pipe engineering fittings for petrochemical, chemical, fertilizer, power, coal chemical, nuclear, and urban gas projects. We mainly produce and manufacture various types of welded pipe fittings, forged pipe fittings, flanges, and special pipeline components.

Customer requirements for processing sheet metal:

What needs to be processed is 316 stainless steel plate. The customer's plate is 3000mm wide, 6000mm long, and 8-30mm thick. A 16mm thick stainless steel plate was processed on site, and the groove is a 45 degree welding bevel. The bevel depth requirement is to leave a 1mm blunt edge, and all the rest are processed.

According to the requirements, our company recommends the model GMMA-80A plate edge milling machine to the customer:

| Product Model | GMMA-80A | Processing board length | >300mm |

| Power Supply | AC 380V 50HZ | Bevel angle | 0°~60°Adjustable |

| Total power | 4800w | Single bevel width | 15~20mm |

| Spindle speed | 750~1050r/min | Bevel width | 0~70mm |

| Feed Speed | 0~1500mm/min | Blade diameter | φ80mm |

| Thickness of clamping plate | 6~80mm | Number of blades | 6pcs |

| Clamping plate width | >80mm | Workbench height | 700*760mm |

| Gross weight | 280kg | Package size | 800*690*1140mm |

Post time: Dec-04-2024