Those who have used a beveling machine know that the beveling machine blade plays a crucial role in cutting and beveling metal sheets and pipes. The blade can accurately and efficiently create the desired bevel when beveling sheets or pipes. Today we will discuss what factors need to be considered in the selection of beveling machine blades.

metal edge beveling machine blades are designed to meet the specific requirements of the cutting process. It’s designed to withstand the rigors of cutting hard materials while maintaining sharpness and durability. The quality of the blade directly affects the quality of the bevel, making it a key factor in achieving precise, clean cuts.

One of the main features of a blade is its bevel, which determines the angle at which the material is cut. Different materials may require different bevel angles, and the blade must be able to accommodate these changes. Additionally, the sharpness of the blade is crucial to achieve a clean cut without damaging the material being processed.

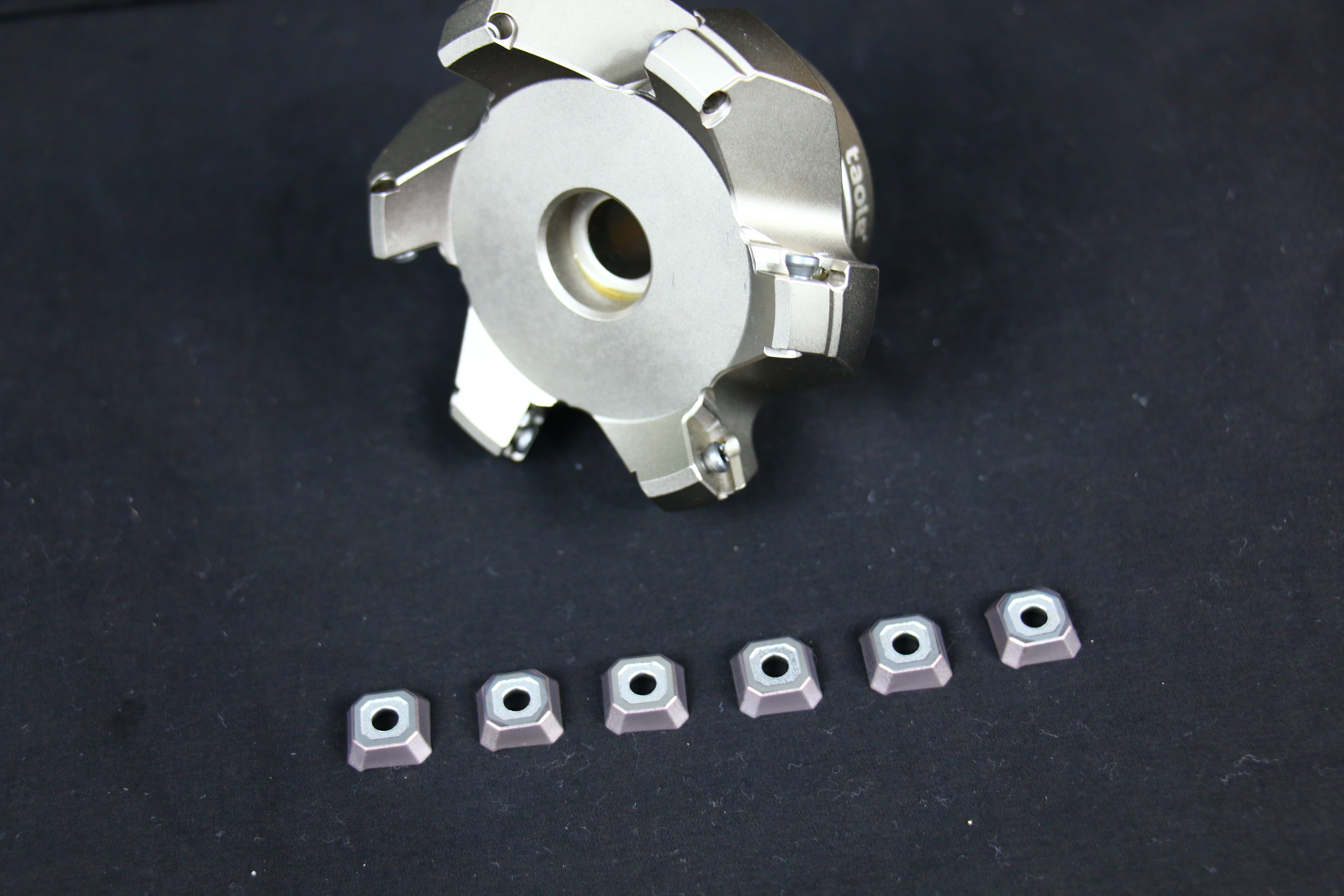

The material of the blade also plays a vital role in its performance. High-quality blades are typically made from durable materials such as high-speed steel, carbide, or diamond, which are known for their hardness and wear resistance. These materials ensure that the blades maintain their sharpness and cutting efficiency over extended periods of use.

The material used for processing metal sheets is an important consideration. Different materials of metal sheets have different hardness and cutting properties, so it is also important to choose the corresponding groove blade.

For harder metal sheets, such as stainless steel and alloy steel, their hardness is higher, which can easily lead to increased tool wear. When processing these materials, it is recommended to choose cutting tools with good wear resistance, usually those with surface coating treatment. These coatings can provide better cutting performance and extend tool life.

For softer metal sheets, such as carbon steel, their hardness is relatively low and the requirements for cutting tools are low. Therefore, conventional steel cutting tools can usually meet processing requirements.

Choose the cutting shape and size of the blade based on the shape and size of the groove. Common groove shapes include V-shaped, U-shaped, and J-shaped to ensure that the blade can provide the desired groove shape.

High quality blades that can be replaced provide the required groove shape.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772 email: commercial@taole.com.cn

Post time: Apr-29-2024