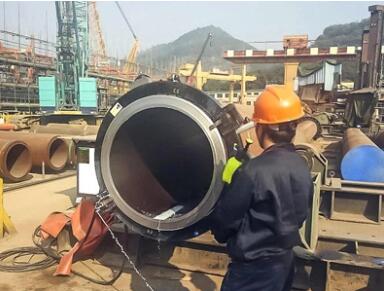

We all know that pipe cold cutting and bevelling machine is a specialized tool for chamfering and beveling the end face of pipelines or flat plates before welding. It solves the problems of non-standard angles, rough slopes, and high working noise in flame cutting, polishing machine grinding and other operating processes. It has the advantages of simple operation, standard angles, and smooth surfaces. So what are its characteristics?

1. split frame pipe cutting and beveling machine production equipment: fast travel speed, stable processing quality, and no need for manual assistance during operation;

2. Cold processing method: does not change the material metallography, does not require subsequent grinding, and improves welding quality;

3. Low investment, unlimited processing length;

4. Flexible and portable! Suitable for both large-scale production and flexible application in welding sites;

5. One operator can take care of multiple devices simultaneously, with simple operating conditions;

6. Suitable for processing various materials such as plain carbon steel, high-strength steel, stainless steel, heat-resistant alloys, aluminum alloys, etc.

7. At a speed of 2.6 meters per minute, a welding groove with a width of 12 millimeters (plate thickness below 40 millimeters and material strength of 40 kg/mm2) is automatically processed in one go.

8. By replacing the groove cutter, six standard groove angles of 22.5, 25, 30, 35, 37.5, and 45 can be obtained.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Jan-29-2024