How to make a U/J bevel joint for pre-welding?

How to choose a beveling machine for metal sheet processing?

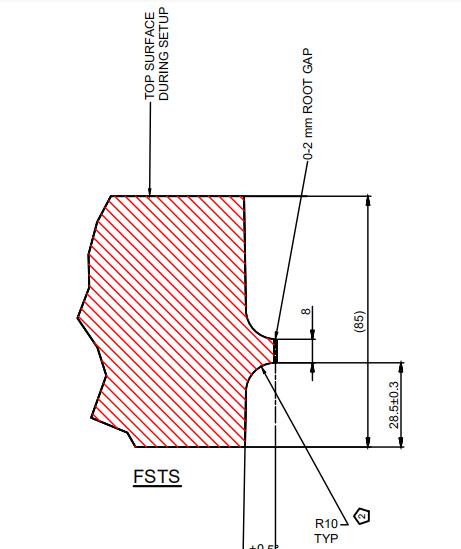

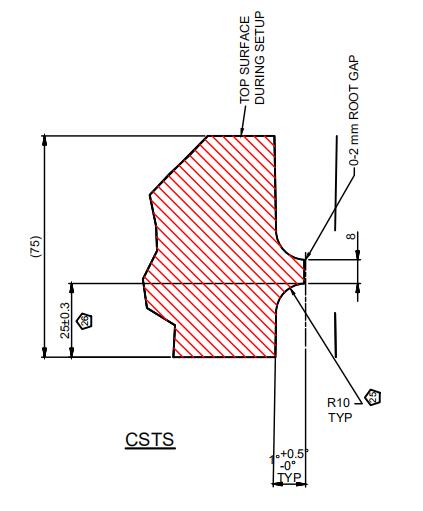

Below drawing reference for bevel requirements from customer. Plate thickness upto 80mm. Request to make double side beveling with R8 and R10.How to Choose a beveling machine for such mild steel metal sheet?

|

|

For efficiency beveling operation. We did suggest and provide solution with a CNC PLATE EDGE MILLING MACHINE.

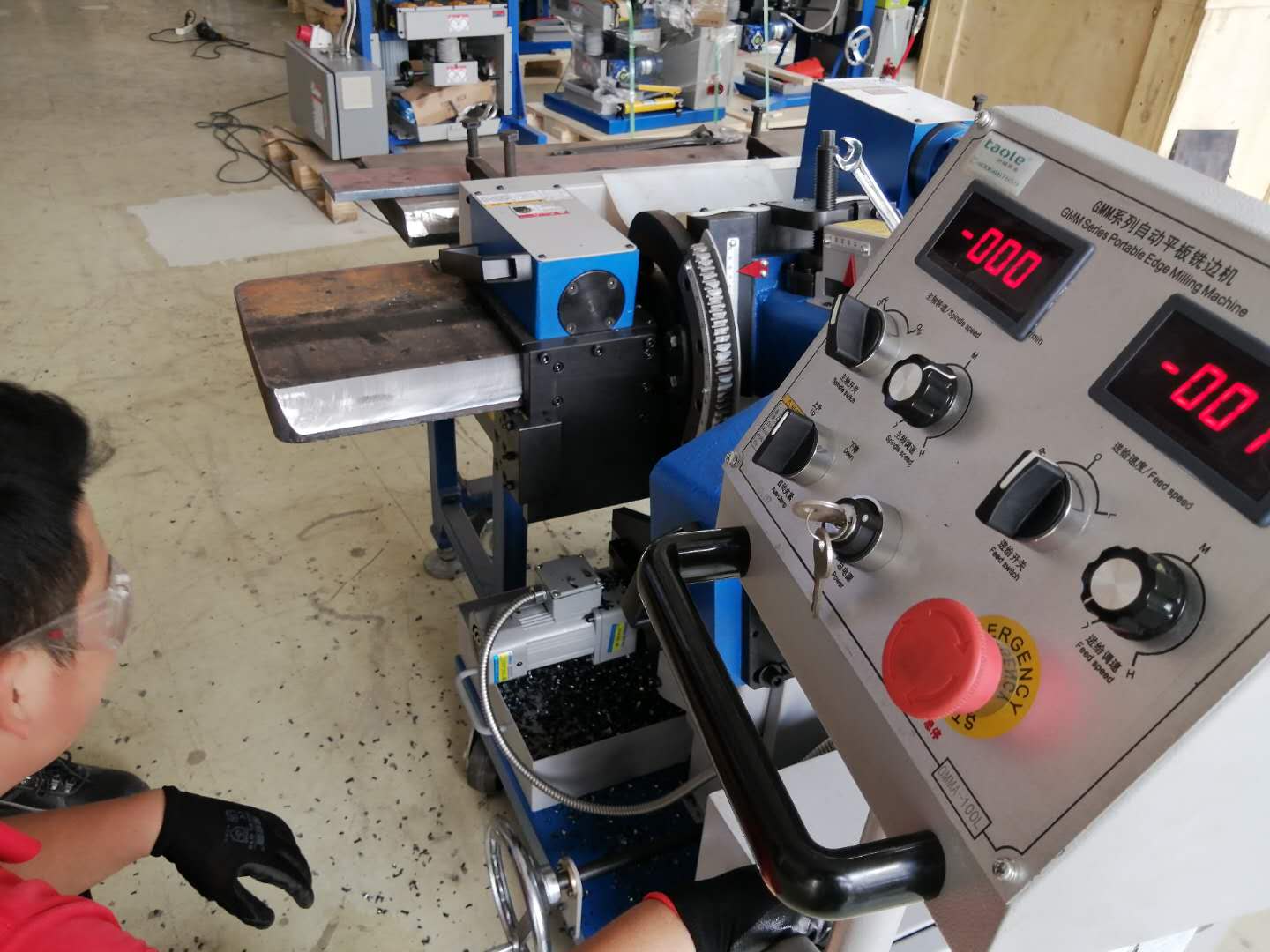

But Customer feedback this U/J type bevel jiont for single projects only. Generally. We did supply wth GMMA-100L metal sheet beveling machine

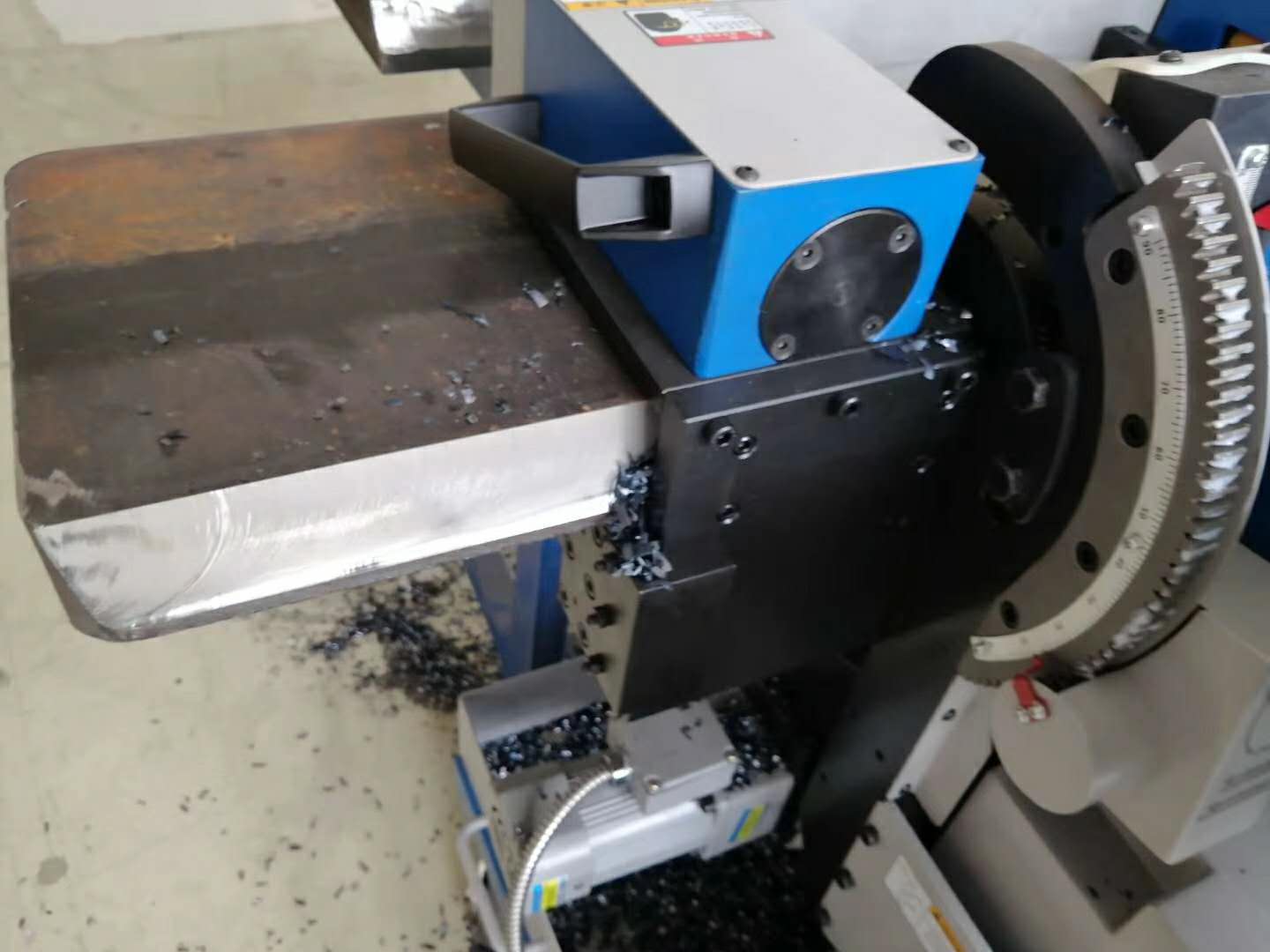

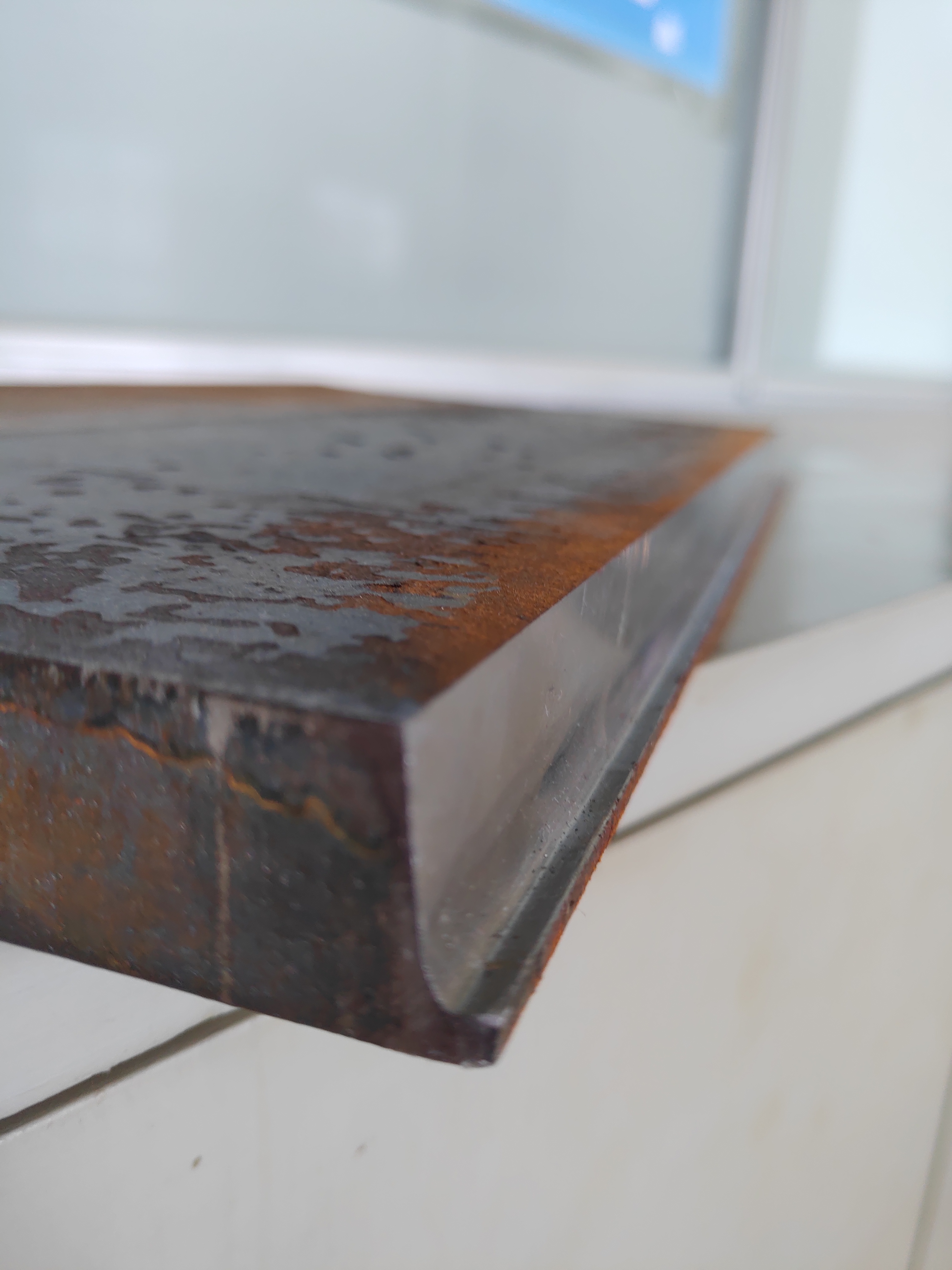

Below testing on a plate thickness 60mm for U R10 bevel by GMMA-100L METAL SHEET BEVELING MACHINE

|

|

Plate thickness 60mm, Plate length at 600mm, Width at 350mm. R10 U bevel with 2mm Root Face for single J bevel only.

Due to the heavy duty plate thickness and small size by GMMA-100L metal sheet beveling machine. It takes 6-8 Cut to achieve bevel. It is not much efficiency as a beveling machine manufacture but customer is happy with that .

|

|

For U/J bevel processing by Walking Type Beveling Machine. We are having two models for option. It depends on customer’s meatl sheet specification and bevel sizes.

1) GMMA-60L Steel Sheet Edge Milling Machine

2) GMMA-100L Steel Sheet Edge Milling Machine

|

|

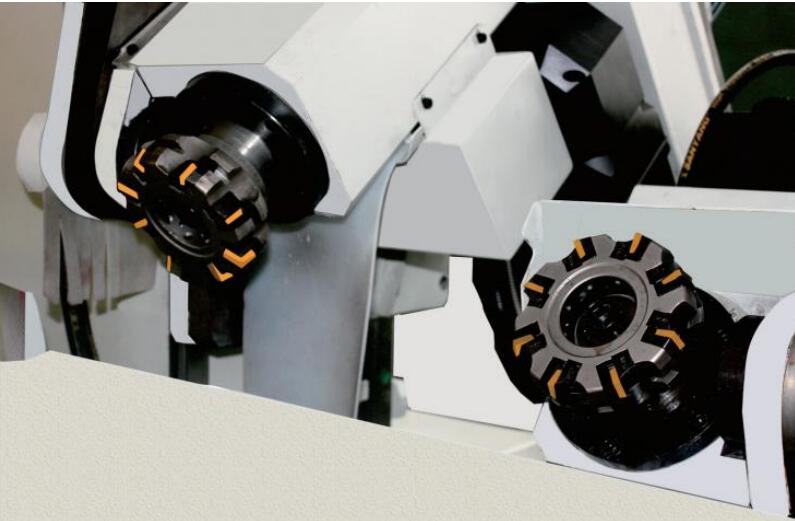

If require a higher efficiency solution with wider working range. We have bevel solution with a CNC table type metal edge milling machine. Which can design with Double Head Milling. Below picture for reference.

|

|

Pls feel free to us if you interested to have more information.

Email: info@taole.com.cn Tel: +86 13917053771

SHANGHAI TAOLE MACHINE CO.,LTD

Marketing Depart

Post time: Sep-04-2020