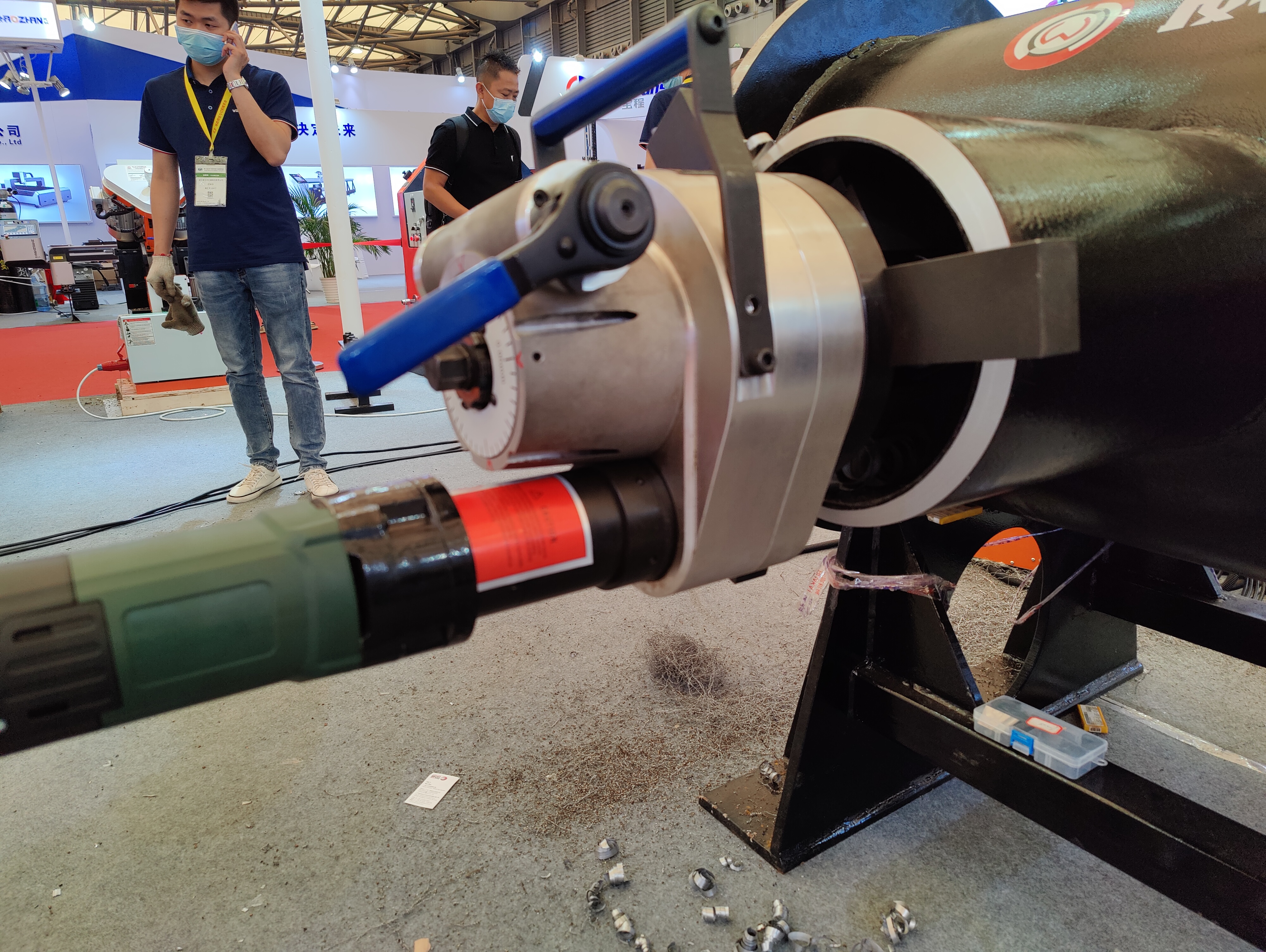

The pipe beveling machine can achieve the functions of pipe cutting, beveling processing, and end preparation. Facing such a common machine, it is very important to learn daily maintenance in order to extend the service life of the machine. So what are the things to pay attention to when maintaining the pipeline beveling machine? Today, let me introduce you to you.

1. Before changing the cutting angle, the cutting plate must be pulled to the root of the cutting stand and locked to prevent collision with the tool holder assembly.

2. In general, the product does not need to be adjusted, just keep the gears lubricated regularly. If the tool holder assembly swings during rotation, the spindle round nut can be adjusted.

3. When cutting, the alignment is not accurate. The tension rod nut should be loosened to adjust the installation position of the support shaft assembly and the workpiece, in order to maintain their coaxiality.

4. After processing each groove, it is necessary to promptly clean the iron filings and debris on the screw and sliding parts, wipe them clean, add oil, and use them again.

5. To ensure the mechanical performance of the product, the body assembly must be suspended and inserted into the support shaft assembly during use.

6. When the beveling machine is not used for a long time, the exposed metal parts should be coated with oil and packed for storage.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Jan-29-2024