Plate Bevel Sector Plates are specialized components used in a wide variety of engineering and manufacturing applications. This unique design combines the advantages of flat plate technology with the precision of beveling to create a versatile and efficient product.

The core of a scalloped plate is a flat surface that is carefully machined to achieve a precise bevel. This design is particularly advantageous in applications where fluid dynamics and airflow are critical. The scalloped shape allows for optimal force distribution and improves the efficiency of systems such as HVAC units, turbines, and other machinery that rely on airflow management.

One of the main advantages of using metal sheet beveling machine to process scalloped plates is its ability to reduce turbulence and improve the overall performance of the system. Beveled edges facilitate smoother transitions between surfaces, minimizing drag and enhancing the flow of air or other fluids. This is especially important in high-performance environments where every detail can impact efficiency and effectiveness

Recently, our company received a request to process fan-shaped plates. The specific situation is as follows.

The workpiece of the fan-shaped plate is a 25mm thick stainless steel plate, and both the inner and outer fan-shaped surfaces need to be machined at a 45 degree angle.

19mm deep, with a 6mm blunt edge welding bevel below.

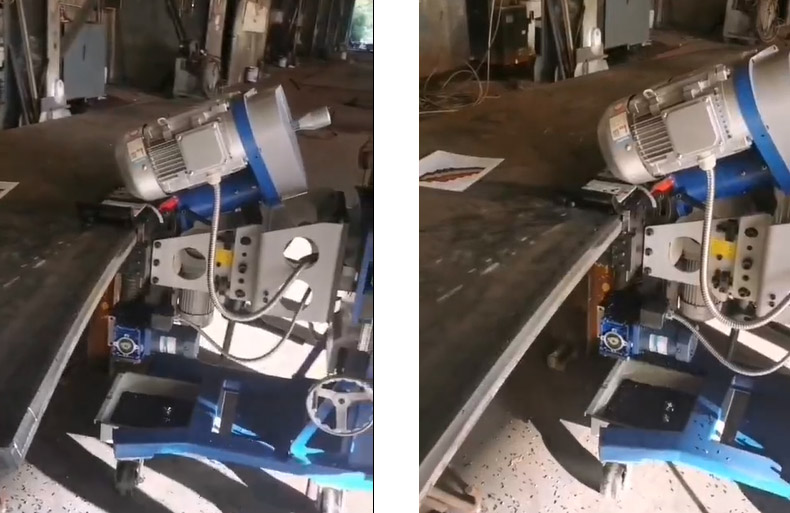

Based on the customer's situation, we recommend using the TMM-80R edge milling machine for chamfering, and have made some modifications according to their process requirements.

The TMM-80R plate beveling machine is a reversible beveling machine that can process V/Y bevels, X/K bevels, and milling edges after plasma cutting of stainless steel.

Product parameters

|

Model |

TMM-80R |

Processing board length |

>300mm |

|

Power supply |

AC 380V 50HZ |

Bevel angle |

0°~+60°Adjustable |

|

Total power |

4800w |

Single bevel width |

0~20mm |

|

Spindle speed |

750~1050r/min |

Bevel width |

0~70mm |

|

Feed Speed |

0~1500mm/min |

Blade diameter |

Φ80mm |

| Thickness of clamping plate |

6~80mm |

Number of blades |

6pcs |

| Clamping plate width |

>100mm |

Workbench height |

700*760mm |

|

Gross weight |

385kg |

Package size |

1200*750*1300mm |

Technicians and on-site staff discuss process details.

One cut for the inner slope and one cut for the outer slope, with very high efficiency of 400mm/min

Post processing effect display:

Post time: Feb-26-2025