In the power transmission industry, the efficiency and reliability of infrastructure are paramount. One of the critical components that contribute to this efficiency is the steel plate beveling machine. This specialized equipment is designed to prepare steel plates for welding, ensuring that joints are strong and durable, which is essential for the high-stress environments found in power transmission applications.

The beveling machine for metal sheet works by creating precise bevels on the edges of steel plates. This process enhances the surface area for welding, allowing for deeper penetration and stronger welds. In the power transmission sector, where components such as towers, pylons, and substations are subjected to significant mechanical stress, the integrity of welds is crucial. A well-beveled edge not only improves the quality of the weld but also reduces the likelihood of defects that could lead to failures.

Shanghai Transmission Technology Co., Ltd. was established on May 15, 2006. The company's business scope includes the "four technical" services in the professional technical field of electro mechanical hydraulic equipment, sales of computer software and hardware, office supplies, wood, furniture, building materials, daily necessities, chemical products (excluding dangerous goods), etc.

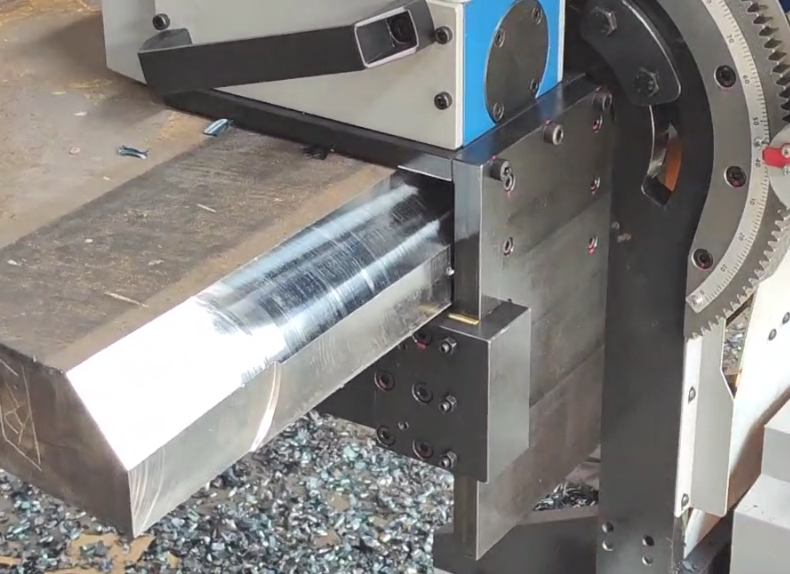

The customer's requirement is to process a batch of 80mm thick steel plates with a 45 ° bevel and a depth of 57mm. Based on the customer's requirements, we recommend our 100L plate beveling machine, and the clamping thickness is customized according to the customer's needs.

Product parameters table

|

Power Supply |

AC 380V 50HZ |

|

Power |

6400W |

|

Cutting Speed |

0-1500mm/min |

|

Spindle speed |

750-1050r/min |

|

Feed motor speed |

1450r/min |

|

Bevel width |

0-100mm |

|

One trip slope width |

0-30mm |

|

Milling angle |

0°-90°(arbitrary adjustment) |

|

Blade diameter |

100mm |

|

Clamping thickness |

8-100mm |

|

Clamping width |

100mm |

|

Processing board length |

>300mm |

|

Product weight |

440kg |

On site processing display:

The steel plate is fixed on the fixture rack, and the technical personnel conduct on-site testing to achieve the 3-cut completion of the groove process. The groove surface is also very smooth and can be directly welded automatically without the need for further polishing

Processing effect display:

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Nov-15-2024