Customer background introduction:

A certain boiler factory is one of the earliest large-scale enterprises established in New China specializing in the production of power generation boilers. The company's main products and services include power plant boilers and complete sets of equipment, large heavy-duty chemical equipment, power plant environmental protection equipment, special boilers, boiler renovation, building steel structures, etc.

After communicating with the customer, we learned about their processing requirements:

The workpiece material is 130+8mm titanium composite plate, and the processing requirements are L-shaped groove, with a depth of 8mm and a width of 0-100mm. The composite layer is peeled off.

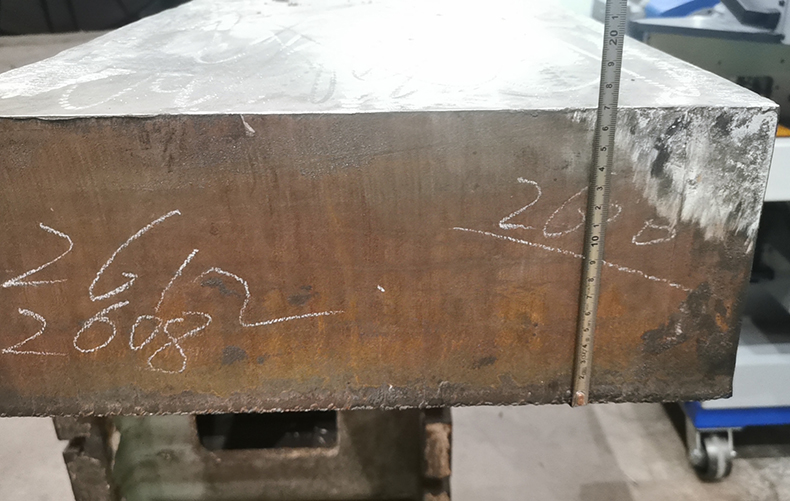

The specific shape of the workpiece is shown in the following figure:

138mm thick, 8mm titanium composite layer.

Due to the special process requirements of the customer compared to conventional requirements, after repeated communication and confirmation between the technical teams of both parties, the Taole GMMA-100L plate edge milling machine was selected for this batch of thick plate processing, and some process modifications were made to the equipment.

|

Power Supply |

Power |

Cutting Speed |

Spindle speed |

Feed motor speed |

Bevel width |

One trip slope width |

Milling angle |

Blade diameter |

|

AC 380V 50HZ |

6400W |

0-1500mm/min |

750-1050r/min |

1450r/min |

0-100mm |

0-30mm |

0°-90°Adjustable |

100mm |

The staff communicates with the user department on the details of machine operation and provides training and guidance.

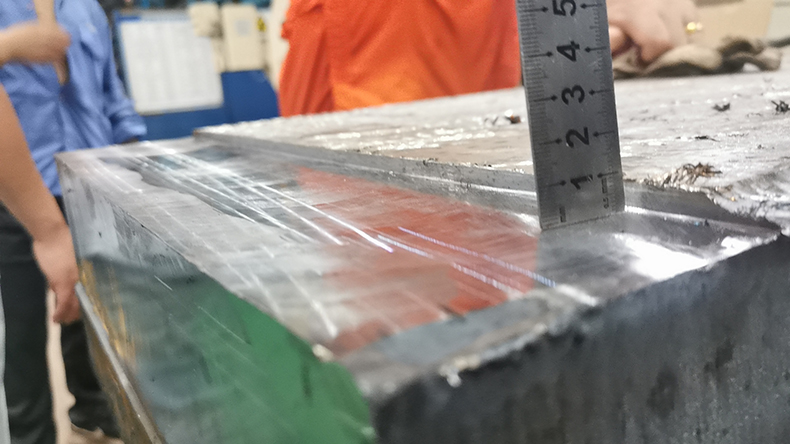

Post processing effect display:

Composite layer with a width of 100mm:

Depth of composite layer 8mm:

The customized GMMA-100L metal plate beveling machine has a large single processing volume, high efficiency, and can also achieve the removal of composite layers, U-shaped and J-shaped grooves, suitable for processing various thick plates.

For further insteresting or more information required about Edge milling machine and Edge Beveler. please consult phone/whatsapp +8618717764772

email: commercial@taole.com.cn

Post time: Feb-17-2025