● Enterprise case introduction

The main business scope of a steel group company in Zhejiang includes: stainless steel pipes, stainless steel products, pipe fittings, elbows, flanges, valves and fittings research and development, manufacturing, sales, Technology development in the field of stainless steel and special steel technology, etc.

● Processing specifications

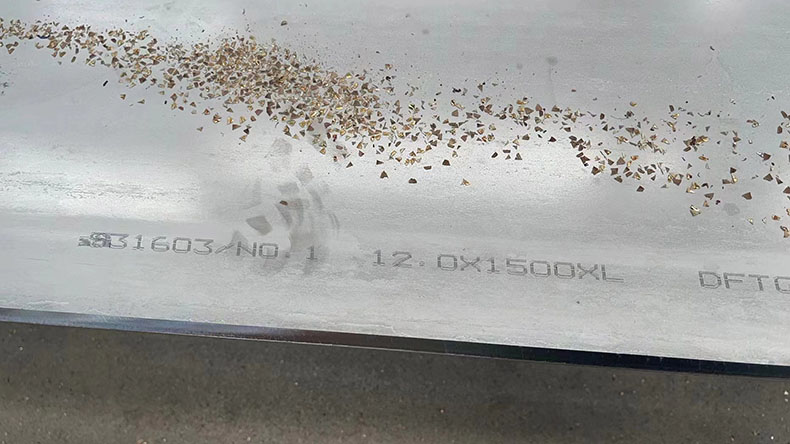

The processing material is S31603 (size 12*1500*17000mm), the processing requirements are groove angle of 40 degrees, leave 1mm obtuse edge, processing depth 11mm, one processing is completed.

● Case solving

According to the customer's process requirements, we recommend Taole GMMA-80A edge milling machine.GMMA-80A beveling machine with 2 motors for plate thickness 6-80mm, bevel angel 0-60 degree, Max width could reach 70mm. It is automatic waling along with plate edge and speed adjustable. Rubber Roller for plate feeding availed for both small plate and big plates. Widely used for carbon steel , stainless steel and alloy steel metal sheets for welding preparation.

Since the customer needs to process 30 plates per day, and each equipment needs to process 10 plates per day, the proposed plan is to use the model GMMA-80A (automatic walking beveling machine), one worker at the same time. Looking at the three equipment, not only meet the production capacity, but also greatly save labor costs. The efficiency and effect of on-site use have been recognized and praised by customers. This is the on-site material S31603 (size 12*1500*17000mm), the processing requirement is groove angle of 40 degrees, leave 1mm blunt edge, processing depth 11mm, the effect after one processing is completed.

This is the effect of the pipe assembly after the steel plate is processed and the groove is welded and formed. After using our edge milling machine for a period of time, customers reported that the processing technology of steel plate has been greatly improved, and the processing efficiency has doubled while reducing the difficulty of processing.

Introducing the GMMA-80A Sheet Metal Edge Beveling Machine - the ultimate solution for all your bevel cutting and cladding removal needs. This versatile machine is designed to process a wide variety of plate materials including mild steel, stainless steel, aluminum alloys, titanium alloys, Hardox and duplex steels.

With the GMMA-80A, you can easily achieve precise, clean bevel cuts, making it ideal for a variety of applications in the welding industry. Bevel cutting is a critical step in weld preparation, ensuring proper fit and alignment of the metal plates for a strong and seamless weld. By using this efficient machine, you can significantly increase your productivity and weld quality.

One of the key features of the GMMA-80A is its flexibility to handle different plate thicknesses and angles. The machine is equipped with adjustable guide rollers, allowing you to easily set the desired bevel angle according to your requirements. Whether you need a straight bevel or a specific angle, this machine delivers exceptional precision and consistency.

Additionally, GMMA-80A is known for its superior performance and durability. It is constructed of high-quality materials to ensure long-term reliability and efficiency. The sturdy construction also contributes to its stability and precise handling, reducing the chance of errors or inaccuracies in bevel cutting.

Another notable advantage of the GMMA-80A is its user-friendly design. The machine is equipped with an intuitive control panel that allows the operator to easily adjust settings and monitor the cutting process. Its ergonomic features ensure comfortable handling even during prolonged use.

To sum up, GMMA-80A metal plate beveling machine is an essential tool in the welding industry. The machine's ability to handle a wide variety of materials and achieve precise bevel cuts will undoubtedly enhance your weld preparation process. Invest in the GMMA-80A today and experience the increased productivity, quality and efficiency in your operations.

Post time: Jul-14-2023