Shipbuilding is a complex and demanding field where the manufacturing process needs to be precise and efficient. Edge milling machines are one of the key tools that are revolutionizing this industry. This advanced machine plays a vital role in shaping and finishing the edges of various components used in ship construction, ensuring they meet the stringent quality standards required for marine applications.

Today, I would like to introduce a shipbuilding and repair company located in Zhejiang Province. It is primarily engaged in the manufacturing of railway, shipbuilding, aerospace, and other transportation equipment.

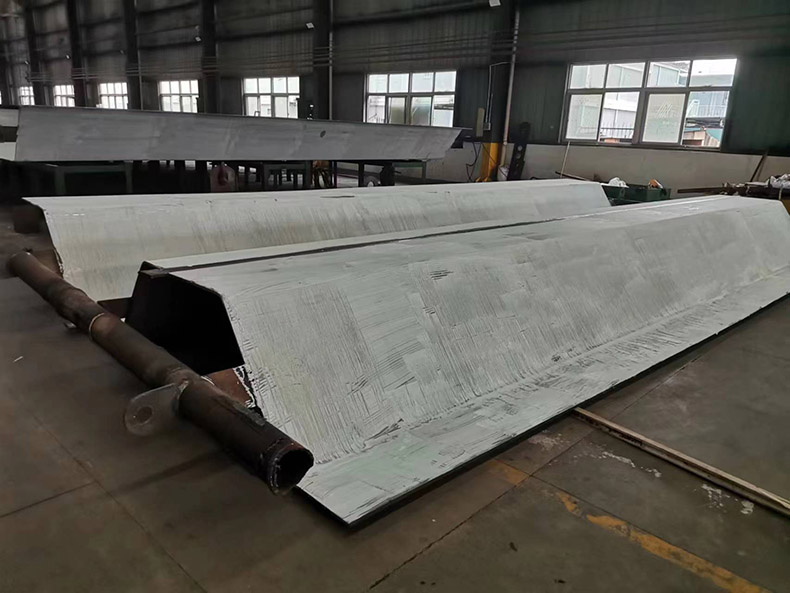

The customer requires on-site processing of UNS S32205 7 * 2000 * 9550 (RZ) workpieces, Mainly used for storage warehouses of oil, gas and chemical ships, their processing requirements are V-shaped grooves, and X-shaped grooves need to be processed for thicknesses between 12-16mm.

We recommend the GMMA-80R plate beveling machine to our customers and have made some modifications according to the process requirements.

The GMM-80R reversible beveling machine for metal sheet can process V/Y groove, X/K groove, and stainless steel plasma cutting edge milling operations.

Product parameters

| PRODUCT MODEL | GMMA-80R | Processing board length | >300mm |

| Power supply | AC 380V 50HZ | Bevel angle | 0°~±60°Adjustable |

| Total power | 4800w | Single bevel width | 0~20mm |

| Spindle speed | 750~1050r/min | Bevel width | 0~70mm |

| Feed Speed | 0~1500mm/min | Blade diameter | φ80mm |

| Thickness of clamping plate | 6~80mm | Number of blades | 6pcs |

| Clamping plate width | >100mm | Workbench height | 700*760mm |

| Gross weight | 385kg | Package size | 1200*750*1300mm |

Processing process display:

The model used is GMM-80R (automatic walking edge milling machine), which produces grooves with good consistency and high efficiency. Especially when making X-shaped grooves, there is no need to flip the plate, and the machine head can be flipped to make a downhill slope, greatly saving the time for lifting and flipping the plate. The independently developed machine head floating mechanism can also effectively solve the problem of uneven grooves caused by uneven waves on the plate surface.

Welding effect display:

Post time: Dec-16-2024