New Delivery for Steel plate bevel machine for fabrication prep to Swiss Factory

Short Description:

New Delivery for Steel plate bevel machine for fabrication prep to Swiss Factory Detail:

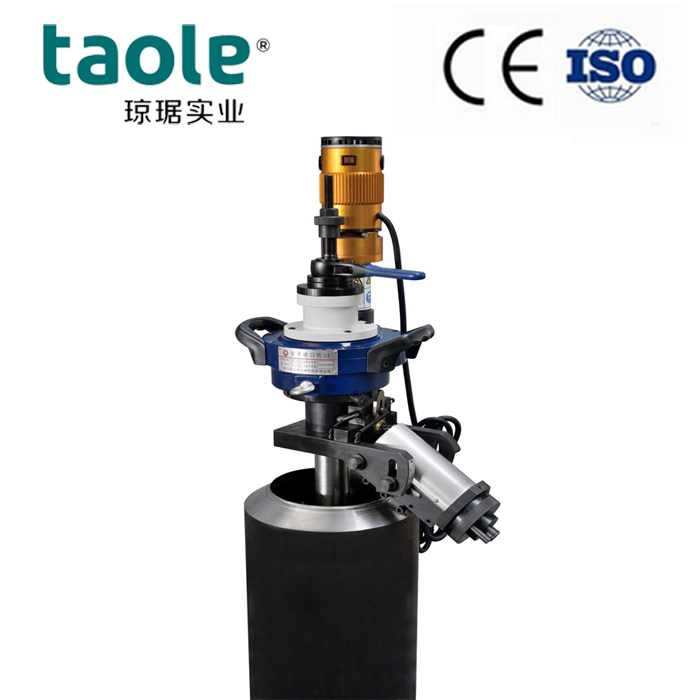

GMMA-80A steel plate bevel machine for fabrication prep

Products Introduction

GMMA-80A steel plate beveling machine for fabrication preparation with two motors. Wide working range of Clamp thickness 6-80mm, bevel angel 0-60 degree adjustable and max bevel with could reach 70mm. The best solution on beveling & milling process for weld preparation.

There are 2 processing Way:

Model 1: Cutter catch the steel and lead into the machine to complete job while processing small steel plates.

Model 2: Machine will travel along the edge of steel and complete job while processing large steel plates.

Specifications

| Model No. | GMMA-80A steel plate bevel machine for fabrication prep |

| Power Supply | AC 380V 50HZ |

| Total Power | 4800W |

| Spindle Speed | 750-1050r/min |

| Feed Speed | 0-1500mm/min |

| Clamp Thickness | 6-80mm |

| Clamp Width | >80mm |

| Process Length | >300mm |

| Bevel angel | 0-60 degree adjustable |

| Single Bevel Width | 15-20mm |

| Bevel Width | 0-70mm |

| Cutter Plate | 80mm |

| Cutter QTY | 6PCS |

| Worktable Height | 700-760mm |

| Travel Space | 800*800mm |

| Weight | N.W 245KGS G.W 280KGS |

| Packaging Size | 800*690*1140mm |

Note: Standard Machine including 1pc cutter head + 2 set of Inserts + Tools in case + Manual Operation

Fetures

1. Available for metal plate Carbon steel,stainless steel, aluminium etc

2. Can process “V”,”Y” , 0 degree milling, vary type of bevel joint

3. Milling Type with High Previous can reach Ra 3.2-6.3 for surface

4.Cold Cutting, energy saving and Low Noise, More safe and environmental with OL protection

5. Wide working range with Clamp thickness 6-80mm and bevel angel 0-60 degree adjustable

6. Easy Operation and high efficiency

7. More stable performance with 2 motors

Bevel Surface

Application

Widely used in aerospace, petrochemical industry, pressure vessel, shipbuilding, metallurgy and unloading processing factory welding manufacturing field.

Exhibition

Packaging

Product detail pictures:

Related Product Guide:

Buying a Milling Machine – Consider Its Types and Specifications

Types of Die Cutting Machines

abide by the contract", conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for New Delivery for Steel plate bevel machine for fabrication prep to Swiss Factory, The product will supply to all over the world, such as: Lithuania, Italy, France, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.