ID mounted Pipe Beveling Machine ISE-80

Short Description:

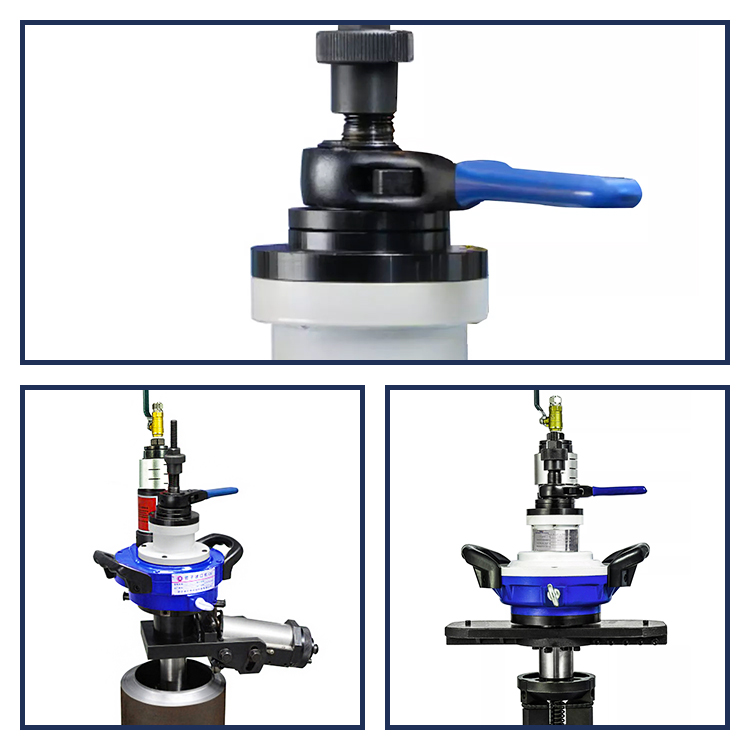

ISE Models id-mounted pipe beveling machine, with the advantages of light weight, easy operation. A draw nut is tightened which expands the mandrel blocks up a ramp and against the id surface for positive mounting, self centered and squared to the bore. It can work with various material pipe,beveling angel as per requirements.

FEATURES AT A GLANCE

TAOLE ISE/ISP series of pipe beveling machines can face and bevel all type of pipe ends, pressure vessel and flanges. The machine adopts "T" shape structure design to realize the minimal radial working space. With the light weight, it is portable and can be used on-site working situation. The machine is applicable to end face machining of various grades of metal pipes, such as carbon steel, stainless steel and alloy steel. It is widely applied in heavy type pipe lines of Petroleum, chemical natural gas, power supply construction, boiler and nuclear power.

Product features

1.Cold cutting, without influence the material of the pipe

2.ID mounted, adopt T structure

3.Varity of beveling shape: U, Single-V, double-V,J beveling

4.It can also be used for repairing inner wall and deep hole processing.

5.Working range: Each model with a wide working range for operation.

6.Driven motor: Pneumatic and Electric

7.Customized machine is acceptable

MODEL & RELATED

| Model Type | Spec | Capacity Inner Diameter | Wall thickness | Rotation Speed |

| ID MM | Standard /MM | |||

|

30 |

18-28 |

≦15 |

50r/min |

|

|

80 |

28-76 |

≦15 |

55r/min |

|

|

120 |

40-120 |

≦15 |

30r/min |

|

|

159 |

65-159 |

≦20 |

35r/min |

|

|

252-1 |

80-240 |

≦20 |

18r/min |

|

|

252-2 |

80-240 |

≦75 |

16r/min |

|

|

352-1 |

150-330 |

≦20 |

14r/min |

|

|

352-2 |

150-330 |

≦75 |

14r/min |

|

|

426-1 |

250-426 |

≦20 |

12r/min |

|

|

426-2 |

250-426 |

≦75 |

12r/min |

|

|

630-1 |

300-600 |

≦20 |

10r/min |

|

|

630-2 |

300-600 |

≦75 |

10r/min |

|

|

850-1 |

600-820 |

≦20 |

9r/min |

|

|

850-2 |

600-820 |

≦75 |

9r/min |

Detail image

Why choose us?

Portability:

Our products are packed with suitcase, which is convenient for carrying and allows you to finish processing outdoors;

Quick installation:

After being taken out from the suitcase, the machine will be ready only by positioning it at the center of the pipe through the ratchet wrench and equipping it with a suitable cutter. The process will not exceed 3 minutes. The machine will start to work after pressing down the motor button;

Safety and reliability:

Through multi-stage deceleration by the internal bevel gear of the angle grinder, the planetary reducer and the internal bevel gear of the main shell, the machines can operate under slow rotating speed while keeping large torque,which makes the beveled end smooth and flat and in high quality, and extends the service of the cutter;

Unique design:

The machines are small and light since their main body is made of aviation aluminum and the sizes of all parts are optimized. The well designed expansion mechanism can realize quick and precise positioning, moreover, the machines are solid enough, with sufficient rigidity for the processing. A variety of available cutters enable the machines to process pipes made from different materials and produce beveled ends with various angles and plain ends. Besides, the unique structure and its self-lubrication function endow the machines with long service life.

Machine Packing

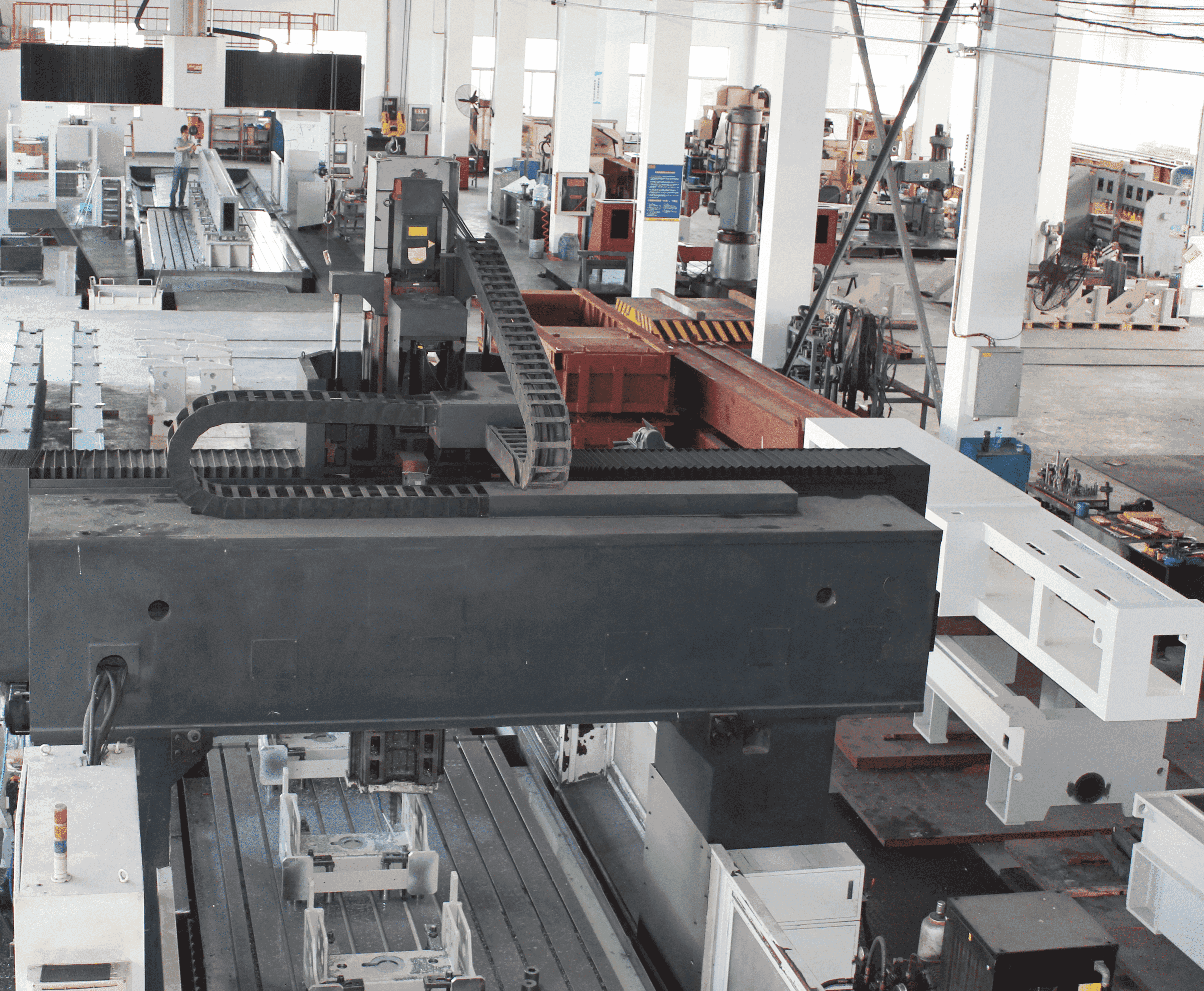

Company Profile

SHANGHAI TAOLE MACHINE CO.,LTD is a Leading professional Manufacturer, Supplier and Exporter of a wide variety of weld preparation machines which widely used in Steel Construction, Shipbuilding, Aerospace, Pressure Vessel , Petrochemical, Oil & Gas and all welding industrial manufacturing. We export our products in more than 50 markets including Australia, Russia, Asia, New Zealand, Europe market, etc. We make contributions to improve the efficiency on metal edge beveling and milling for weld preparation.With our own production team, development team, shipping team, sales and after-sales service team for customer assistance. Our machines are well accepted with high reputation in both domestic and overseas markets with more than 18 years’ experience in this industry since 2004. Our engineer team keep developing and updating machine based on energy saving, high efficiency, safety purpose. Our mission is “QUALITY, SERVICE and COMMITMENT”. Provide the best solution for customer with high quality and great service.

Certifications

FAQ

Q1: What is the power supply of the machine?

A: Optional Power Supply at 220V/380/415V 50Hz. Customized power /motor/logo/Color available for OEM service.

Q2: Why comes multi models and how should I Choose and understand?

A: We have different models based on customer’s requirements. Mainly different on power, Cutter head, bevel angel, or special bevel joint required. Please send a inquiry and share your requirements ( Metal Sheet specification width * length * thickness, required bevel joint and angel). We will present you with best solution based on general conclusion.

Q3: What is the delivery time?

A: Standard machines are stock available or spare parts available which able to be ready in 3-7 days. If you have special requirements or customized service. Normally takes 10-20 days after order confirm.

Q4: What is the warranty period and after sales service?

A: We provide 1 year warranty for machine except wearing parts or consumables. Optional for Video Guide, Online Service or local Service by third party. All spare parts available in both Shanghai and Kun Shan Warehouse in China for fast moving and shipping.

Q5: What is your payment Teams?

A: We welcome and try multi payment terms depends on order value and necessary. Will suggest 100% payment against fast shipment. Deposit and balance % against cycle orders.

Q6: How do you pack it?

A: Small machine tools packed in tool box and carton boxes for safety shipments by courier express. Heavy machines weight higher than 20 kgs packed in wooden cases pallet against safety shipment by Air or Sea. Will suggest bulk shipments by sea considering machine sizes and weight.

Q7: Are you Manufacture and what is your products range?

A: Yes. We are manufacture for beveling machine since 2000.Welcome to visit our factory in Kun shan City. We concentrating on metal steel beveling machine for both plate and pipes against welding preparation. Products including Plate Beveler, Edge Milling Machine, Pipe beveling, pipe cutting beveling machine, Edge rounding /Chamfering, Slag removal with standard and customized solutions.

Welcome to contact us anytime for any inquiry or more informations.