Hot-selling OCP-159 automatic cold pipe cutting beveling machine – Pipe Bevelling

Short Description:

Hot-selling OCP-159 automatic cold pipe cutting beveling machine – Pipe Bevelling Detail:

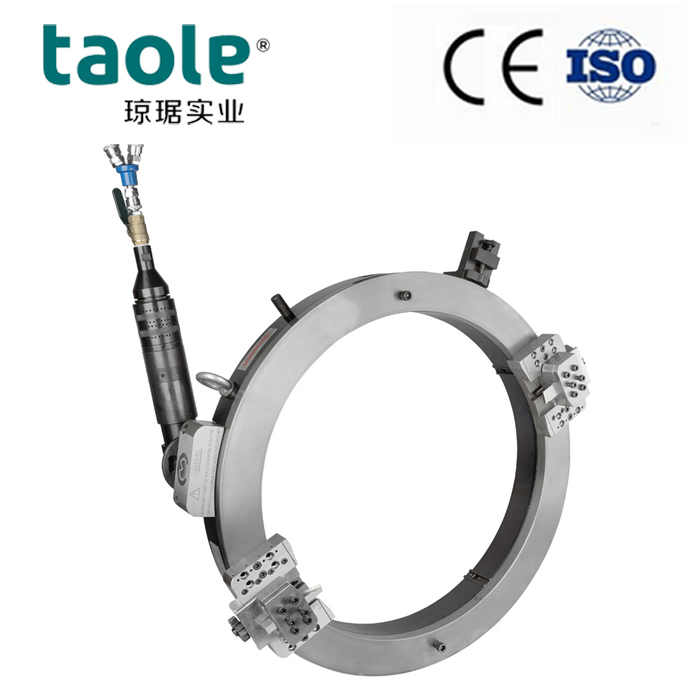

OCP-159 automatic cold pipe cutting beveling machine

Introduction

This series are portable od-mountd frame type pipe cold cutting and beveling machine with advantages of light weight, minimal radial space, easy operation and so on. Split frame design can separate mount the od of the in-lin pipe for strong and stable clamping to process cutting and beveling sumultaneously.

Specification

Power Supply: 0.6-1.0 @1500-2000L/min

| Model NO. | Working Range | Wall Thickness | Rotation Speed | Air Pressure | Air Consumption | |

| OCP-89 | φ 25-89 | 3/4‘’-3‘’ | ≤35mm | 50 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-159 | φ50-159 | 2‘’-5‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-168 | φ50-168 | 2‘’-6‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-230 | φ80-230 | 3‘’-8‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-275 | φ125-275 | 5‘’-10‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-305 | φ150-305 | 6‘’-10‘’ | ≤35mm | 18 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-325 | φ168-325 | 6‘’-12‘’ | ≤35mm | 16 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-377 | φ219-377 | 8‘’-14‘’ | ≤35mm | 13 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-426 | φ273-426 | 10‘’-16‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-457 | φ300-457 | 12‘’-18‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-508 | φ355-508 | 14‘’-20‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-560 | φ400-560 | 16‘’-22‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-610 | φ457-610 | 18‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-630 | φ480-630 | 20‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-660 | φ508-660 | 20‘’-26‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-715 | φ560-715 | 22‘’-28‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-762 | φ600-762 | 24‘’-30‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-830 | φ660-813 | 26‘’-32‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-914 | φ762-914 | 30‘’-36‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1066 | φ914-1066 | 36‘’-42‘’ | ≤35mm | 9 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1230 | φ1066-1230 | 42‘’-48‘’ | ≤35mm | 8 r/min | 0.6~1.0MPa | 2000 L/min |

Note: Standard machine packaging including : 2 pcs cutter,2pcs of bevel tool +tools + operation manual

Fetures

1. Low axial and radial clearance light weight suitable for working at narrow and complicated site

2. Split frame design can separate to 2 half, easy to process when two end not open

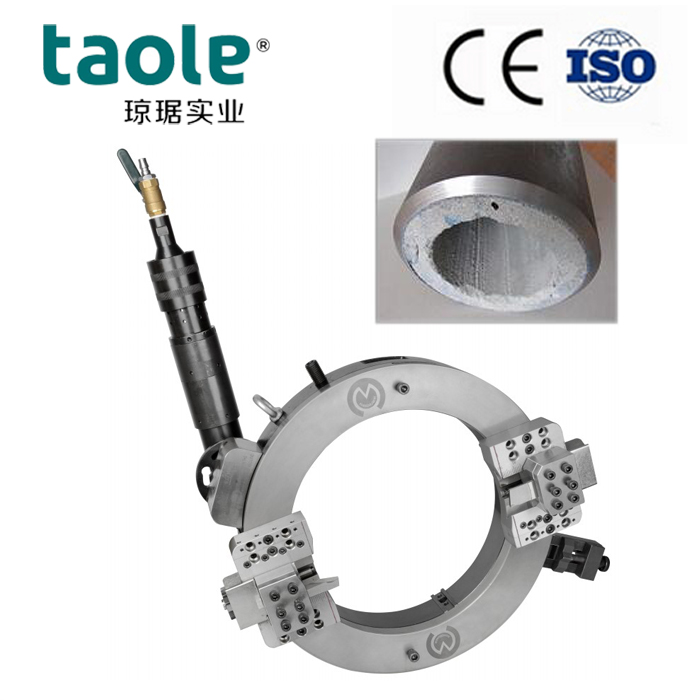

3. This machine can process cold cutting and beveling simultaneously

4. With option for electric, Pneuamtic, Hydraulic ,CNC based on site condition

5. Tool feed automatically with Low noise, long life and stable performance

6. Cold working without Spark , Will not affect the pipe material

7. Can process different pipe material : Carbon steel, stainless steel , alloys etc

8. Explosion Proof, Simple structure makes easy to maintenance

Bevel Surface

Application

Widely used in the fields of petroleum, chemical, natural gas,power plant construction,bolier and nuclear power, pipeline etc.

Customer Site

Packaging

Product detail pictures:

Related Product Guide:

Buying a Milling Machine – Consider Its Types and Specifications

Industrial Cutters and Cutting Machines

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for Hot-selling OCP-159 automatic cold pipe cutting beveling machine – Pipe Bevelling, The product will supply to all over the world, such as: Iran, Armenia, Porto, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!