●Kev taw qhia txog cov ntaub ntawv lag luam

Lub Hoobkas boiler yog lub tuam txhab loj tshaj plaws uas tshwj xeeb hauv kev tsim cov boilers tsim hluav taws xob hauv New China. Lub tuam txhab feem ntau ua haujlwm hauv chaw nres tsheb fais fab boilers thiab cov khoom tiav, cov khoom siv tshuaj hnyav loj, cov khoom siv tiv thaiv ib puag ncig ntawm chaw nres tsheb fais fab, cov boilers tshwj xeeb, kev hloov pauv boiler, kev tsim cov qauv hlau thiab lwm yam khoom thiab cov kev pabcuam.

●Cov lus qhia ua tiav

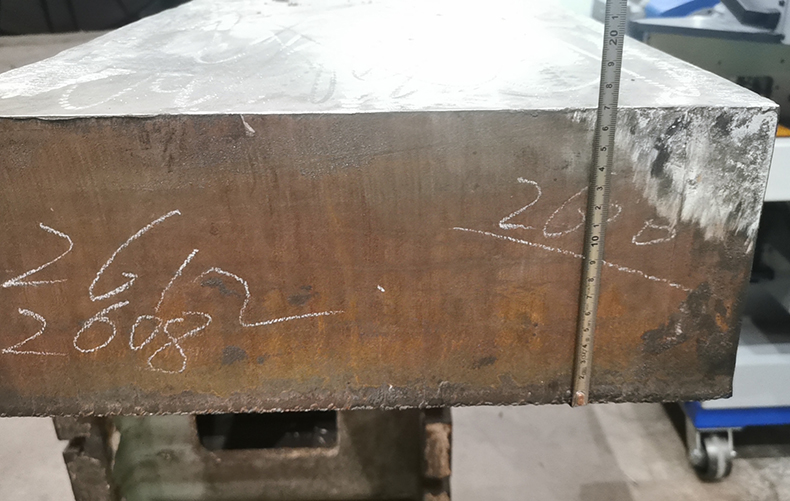

Cov kev cai ua haujlwm: cov khoom siv ua haujlwm yog 130 + 8 hli titanium composite vaj huam sib luag, cov kev cai ua haujlwm yog L-puab groove, tob 8 hli, dav 0-100 hli composite txheej peeling.

Cov khoom ua haujlwm, raws li pom hauv daim duab hauv qab no: 138mm tuab, 8mm titanium composite txheej.

●kev daws teeb meem

Raws li cov neeg siv khoom xav tau, peb pom zoo Taole GMMA-100L lub tshuab ua haujlwm hnyav nrog 2 lub taub hau milling, phaj tuab ntawm 6 txog 100mm, bevel angel ntawm 0 txog 90 degree kho tau. GMMA-100L tuaj yeem ua 30mm ib qho kev txiav. 3-4 qhov kev txiav kom ua tiav bevel dav 100mm uas yog kev ua haujlwm siab thiab pab tau ntau rau kev txuag lub sijhawm thiab tus nqi.

Cov neeg ua haujlwm sib txuas lus cov ntsiab lus ntawm kev ua haujlwm ntawm lub tshuab nrog lub chaw haujlwm neeg siv thiab muab kev qhia txog kev cob qhia.

● Cov nyhuv tom qab ua tiav:

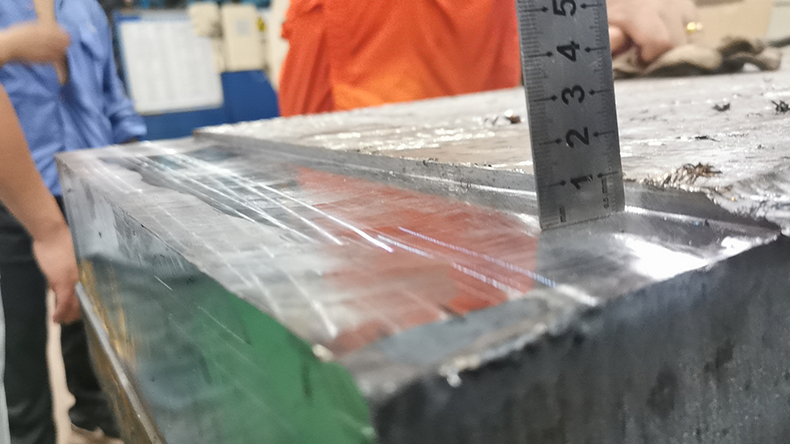

Tshem tawm cov txheej sib xyaw uas dav 100 hli.

Tshem tawm cov txheej sib xyaw kom tob txog 8 hli.

Hauv ntiaj teb kev tsim hlau, qhov tseeb thiab kev ua haujlwm tau zoo yog qhov tseem ceeb heev. Txhua yam khoom uas ua kom yooj yim thiab txhim kho cov txheej txheem yuav raug txais tos zoo siab. Yog vim li ntawd peb thiaj zoo siab los qhia txog GMM-100LY, lub tshuab tswj hwm wireless tshiab tshaj plaws. Tsim tshwj xeeb rau cov hlau hnyav, cov khoom siv zoo kawg no ua kom muaj kev npaj ua tiav tsis tau muaj dua li.

Tso lub zog ntawm lub bevel:

Kev khoov thiab chamfering yog cov txheej txheem tseem ceeb hauv kev npaj cov pob qij txha vuam. Lub GMM-100LY tau tsim tshwj xeeb los ua kom zoo tshaj plaws hauv cov cheeb tsam no, khav txog cov yam ntxwv zoo kawg nkaus kom haum rau ntau hom pob qij txha vuam. Cov kaum sab xis ntawm 0 txog 90 degrees, thiab cov kaum sib txawv tuaj yeem tsim tau, xws li V/Y, U/J, lossis txawm tias 0 txog 90 degrees. Qhov kev hloov pauv no ua kom ntseeg tau tias koj tuaj yeem ua tiav txhua qhov kev sib koom ua ke nrog qhov tseeb thiab ua haujlwm tau zoo tshaj plaws.

Kev Ua Tau Zoo Tshaj Plaws:

Ib qho ntawm cov yam ntxwv zoo tshaj plaws ntawm GMM-100LY yog nws lub peev xwm ua haujlwm rau ntawm cov hlau uas muaj tuab ntawm 8 txog 100 hli. Qhov no nthuav dav nws qhov kev siv, ua rau nws haum rau ntau yam haujlwm. Tsis tas li ntawd, nws qhov dav tshaj plaws ntawm 100 hli tshem tawm ntau cov khoom siv, txo qhov xav tau kev txiav ntxiv lossis cov txheej txheem du.

Kev paub txog kev yooj yim wireless:

Lub sijhawm uas raug khi rau lub tshuab thaum ua haujlwm twb dhau mus lawm. Lub GMM-100LY los nrog lub chaw tswj hwm wireless, uas cia koj txav mus los tau yooj yim hauv koj qhov chaw ua haujlwm yam tsis muaj kev cuam tshuam rau kev nyab xeeb lossis kev tswj hwm. Qhov kev yooj yim niaj hnub no ua rau muaj kev tsim khoom ntau ntxiv, tso cai rau kev txav mus los yooj yim thiab tso cai rau koj siv lub tshuab los ntawm txhua lub kaum sab xis.

Qhia qhov tseeb thiab kev ruaj ntseg:

Lub GMM-100LY muab qhov tseeb thiab kev nyab xeeb tso ua ntej. Nws muaj cov thev naus laus zis siab heev los xyuas kom meej tias txhua qhov kev txiav bevel raug ua tiav raws li qhov tseeb thiab muab cov txiaj ntsig zoo sib xws. Lub tshuab lub cev khov kho ua kom ruaj khov thiab tshem tawm txhua qhov kev co uas yuav cuam tshuam rau qhov tseeb ntawm kev txiav. Nws lub interface yooj yim rau cov kws tshaj lij thiab cov neeg tshiab hauv daim teb no siv tau.

xaus lus:

Nrog lub tshuab GMM-100LY wireless chaw taws teeb tswj hwm daim ntawv beveling, kev npaj hlau tsim tau ib kauj ruam loj mus tom ntej. Nws cov yam ntxwv tshwj xeeb, kev sib raug zoo dav dav thiab kev yooj yim wireless ua rau nws sib txawv ntawm cov neeg sib tw. Txawm hais tias koj ua haujlwm nrog cov ntawv hlau hnyav lossis cov pob qij txha sib txuas, cov khoom siv zoo kawg no lav qhov txiaj ntsig zoo txhua lub sijhawm. Txais yuav qhov kev daws teeb meem tshiab no thiab ua tim khawv rau kev hloov pauv hauv cov txheej txheem ua hlau.

Lub sijhawm tshaj tawm: Lub Yim Hli-04-2023