Kev tsim nkoj yog ib qho kev lag luam nyuaj thiab xav tau ntau yam, xav tau kev tsim kho kom raug thiab cov ntaub ntawv zoo. Ib qho ntawm cov cuab yeej tseem ceeb uas hloov pauv kev lag luam no yogphaj bevelingtshuabCov tshuab ua haujlwm siab heev no ua lub luag haujlwm tseem ceeb hauv kev tsim khoom thiab sib dhos ntawm ntau yam khoom siv nkoj, kom ntseeg tau tias lawv ua tau raws li cov qauv kev nyab xeeb thiab kev ua tau zoo.Phaj ntug beveling tshuabyog tsim los rau kev ua kom raug siab ntawm cov hlau loj. Hauv kev tsim nkoj, cov tshuab no feem ntau yog siv los tsim cov duab thiab cov duab sib txawv uas xav tau rau lub hulls, decks, thiab lwm yam khoom ntawm cov nkoj. Lub peev xwm los tshuab cov hlau phaj rau qhov ntev meej ua rau cov neeg tsim nkoj ua tiav qhov haum zoo meej thaum lub sijhawm sib dhos, uas yog qhov tseem ceeb rau kev tswj hwm kev ncaj ncees thiab kev ruaj khov ntawm lub nkoj.

Lub sijhawm no peb tab tom qhia txog ib pawg neeg ua nkoj loj nyob rau sab qaum teb uas xav tau kev ua cov phaj tshwj xeeb.

Qhov yuav tsum tau ua yog ua kom muaj 45 ° bevel ntawm lub phaj hlau tuab 25 hli, tawm hauv 2 hli ntug blunt ntawm qab rau ib qho kev txiav molding.

Raws li cov neeg siv khoom xav tau, peb cov neeg ua haujlwm kev pom zoo kom siv TaoleTMM-100L tsis siv neegphaj hlauntugtshuab millingFeem ntau yog siv rau kev ua cov phaj tuabbevels thiab kauj ruambevels ntawm cov phaj sib xyaw, nws yog dav siv hauv ntau dhaubevel kev ua haujlwm hauv cov hlab ntsha siab thiab kev tsim nkoj, thiab ua lub luag haujlwm tseem ceeb hauv cov teb xws li petrochemicals, aerospace, thiab kev tsim cov qauv hlau loj.

Qhov ntim ua ib zaug yog loj, thiab qhov dav ntawm qhov nqes hav tuaj yeem ncav cuag 30 hli, nrog kev ua haujlwm siab. Nws kuj tseem tuaj yeem ua tiav kev tshem tawm cov txheej sib xyaw thiab U-puab thiab J-puabcov bevels.

Cov Khoom Siv

| Lub zog fais fab mov | AC380V 50HZ |

| Tag nrho lub zog | 6520W |

| Txo kev siv hluav taws xob | 6400W |

| Qhov ceev ntawm lub ntxaiv | 500 ~ 1050r / feeb |

| Tus nqi pub | 0-1500mm/min (txawv raws li cov khoom siv thiab pub qhov tob) |

| Clamping phaj tuab | 8-100 hli |

| Qhov dav ntawm lub phaj clamping | ≥ 100 hli (ntug tsis yog tshuab) |

| Qhov ntev ntawm lub rooj ua haujlwm | > 300 hli |

| Lub kaum sab xis | 0 ° ~ 90 ° Kho tau |

| Ib qho dav dav | 0-30 hli (nyob ntawm lub kaum sab xis thiab cov khoom siv hloov pauv) |

| Dav ntawm bevel | 0-100 hli (txawv raws li lub kaum sab xis ntawm lub bevel) |

| Lub taub hau txiav | 100 hli |

| Qhov ntau ntawm cov hniav | 7/9 daim |

| Qhov hnyav | 440kg |

Qhov kev sim qauv no yeej coj ntau yam kev cov nyom rau peb lub tshuab, uas yog kev ua haujlwm nrog rab riam puv nkaus. Peb tau kho cov kev teeb tsa ntau zaus thiab ua tau raws li cov txheej txheem xav tau.

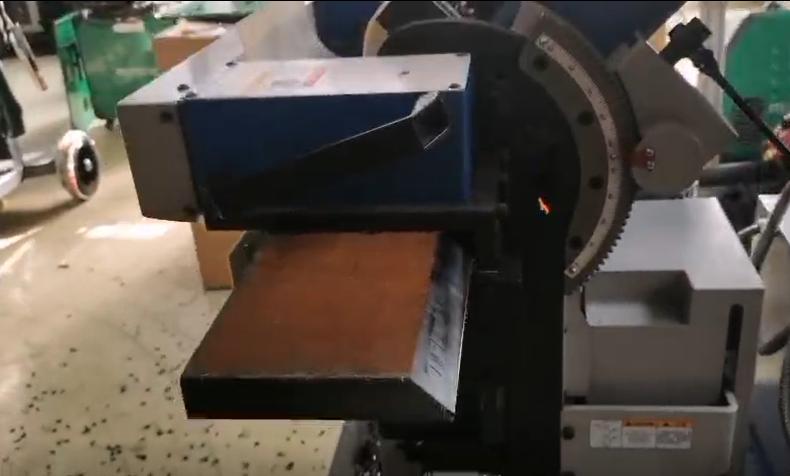

Kev ua qauv qhia txog kev sim:

Cov nyhuv tom qab ua tiav:

Tus neeg siv khoom tau hais tias lawv txaus siab heev thiab tau ua tiav daim ntawv cog lus tam sim ntawd. Peb kuj muaj hmoo heev vim tias kev lees paub ntawm tus neeg siv khoom yog qhov koob meej tshaj plaws rau peb, thiab kev mob siab rau kev lag luam yog peb txoj kev ntseeg thiab kev npau suav uas peb ib txwm ua.

Lub sijhawm tshaj tawm: Lub Yim Hli-18-2025