Handheld Fiber Laser Welding Machine for Metal Welding

Short Description:

Taole Handheld laser welding machine adopts the latest generation of fiber laser and is equipped with independently developed wobble welding head to fill the gap of handheld welding in the laser equipment industry. It has the advantages of simple operation, beautiful weld line, fast welding speed and no consumables. It can weld thin stainless steel plate, iron plate, galvanized plate and other metal materials, which can perfectly replace the traditional argon arc welding Electric welding and other processes. Hand held laser welding machine can be widely used in complex and irregular welding processes in cabinet, kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Product Description

Taole Handheld laser welding machine adopts the latest generation of fiber laser and is equipped with independently developed wobble welding head to fill the gap of handheld welding in the laser equipment industry. It has the advantages of simple operation, beautiful weld line, fast welding speed and no consumables. It can weld thin stainless steel plate, iron plate, galvanized plate and other metal materials, which can perfectly replace the traditional argon arc welding Electric welding and other processes. Hand held laser welding machine can be widely used in complex and irregular welding processes in cabinet, kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Hand-held welding machine mainly option with three models: 1000W, 1500W, 2000W or 3000W.

Handheld Laser Welding Machine Parameter:

|

No. |

Item |

Parameter |

|

1 |

Name |

Hand-held Laser Welding Machine |

|

2 |

Welding Power |

1000W、1500W,2000W、3000W |

|

3 |

Laser wavelength |

1070NM |

|

4 |

Fiber Length |

Normal:10M Max Support:15M |

|

5 |

Operation Mode |

Continuous / Modulation |

|

6 |

Welding Speed |

0~120 mm/s |

|

7 |

Cooling Mode |

Industrial Thermostatic Water Tank |

|

8 |

Operating Ambient Temperature |

15~35 ℃ |

|

9 |

Operating Ambient Humidity |

< 70%(No condensation) |

|

10 |

Welding Thickness |

0.5-3mm |

|

11 |

Welding Gap Requirements |

≤0.5mm |

|

12 |

Operating Voltage |

AV220V |

|

13 |

Machine Size(mm) |

1050*670*1200 |

|

14 |

Machine Weight |

240kg |

No.ItemParameter1NameHand-held Laser Welding Machine2Welding Power1000W,1500W,2000W,3000W3Laser wavelength1070NM4Fiber LengthNormal:10M Max Support:15M5Operation ModeContinuous / Modulation6Welding Speed0~120 mm/s7Cooling ModeIndustrial Thermostatic Water Tank8Operating Ambient Temperature15~35 ºC9Operating Ambient Humidity< 70%(No condensation)10Welding Thickness0.5-3mm11Welding Gap Requirements≤0.5mm12Operating VoltageAV220V13Machine Size(mm)1050*670*120014Machine Weight240kg

Handheld Laser Welding Machine Welding Data:

(This data is for reference only, please refer to the actual data of the proofing; 1000W laser welding equipment can be adjusted to 500W.)

|

Power |

SS |

Carbon Steel |

Galvanized Plate |

|

500W |

0.5-0.8mm |

0.5-0.8mm |

0.5-0.8mm |

|

800W |

0.5-1.2mm |

0.5-1.2mm |

0.5-1.0mm |

|

1000W |

0.5-1.5mm |

0.5-1.5mm |

0.5-1.2mm |

|

2000W |

0.5-3mm |

0.5-3mm |

0.5-2.5mm |

Independent R&D Wobble welding head

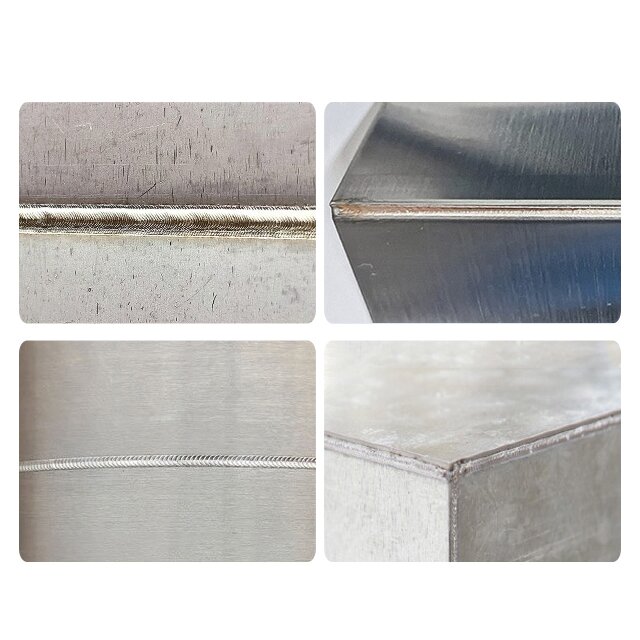

The wobble welding joint is independently developed, with swing welding mode, adjustable spot width and strong welding fault tolerance, which makes up for the disadvantage of small laser welding spot, expands the tolerance range and weld width of machined parts, and obtains better weld line forming.

Technological Characteristics

The weld line is smooth and beautiful, the welded workpiece is free of deformation and welding scar, the welding is firm, the subsequent grinding process is reduced, and the time and cost are saved.

Advantages of Handheld Laser Welding Machine

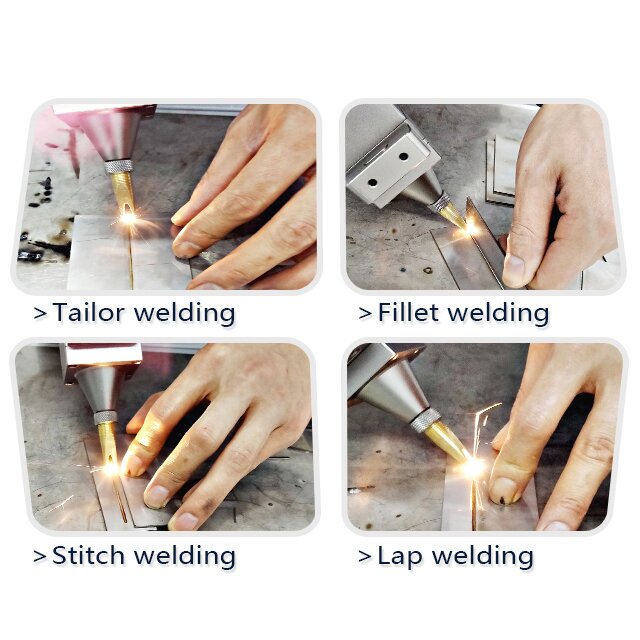

Simple operation, one-time molding, can weld beautiful products without professional welders

Wobble handheld laser head is light and flexible, which can weld any part of the workpiece,

making the welding work more efficient, safe, energy-saving and environmental protection.

.png)

-284x300.png)

-1-300x300.jpg)

-2-300x300.jpg)

-3-300x300.jpg)

-3.jpg)