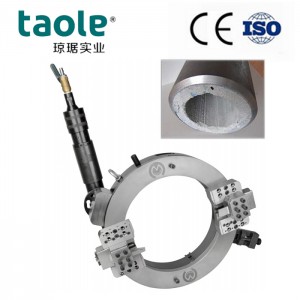

Good Quality China Automatic Feed Plate Cutting and Beveling Machine

Short Description:

OCP models od-mounted pneumatic pipe cold cutting and beveling machine with light weight, minimal radial space . It can separate to two half and easy to operate. Machine can do cutting and beveling simultaneously.

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Good Quality China Automatic Feed Plate Cutting and Beveling Machine, Our company quickly grew in size and name because of its absolute dedication to superior quality manufacturing, large value of goods and great customer provider.

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Beveller, China bevelling machine, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

OCP-159 automatic cold pipe cutting beveling machine

Introduction

This series are portable od-mountd frame type pipe cold cutting and beveling machine with advantages of light weight, minimal radial space, easy operation and so on. Split frame design can separate mount the od of the in-lin pipe for strong and stable clamping to process cutting and beveling sumultaneously.

Specification

Power Supply: 0.6-1.0 @1500-2000L/min

| Model NO. | Working Range | Wall Thickness | Rotation Speed | Air Pressure | Air Consumption | |

| OCP-89 | φ 25-89 | 3/4‘’-3‘’ | ≤35mm | 50 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-159 | φ50-159 | 2‘’-5‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-168 | φ50-168 | 2‘’-6‘’ | ≤35mm | 21 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-230 | φ80-230 | 3‘’-8‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-275 | φ125-275 | 5‘’-10‘’ | ≤35mm | 20 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-305 | φ150-305 | 6‘’-10‘’ | ≤35mm | 18 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-325 | φ168-325 | 6‘’-12‘’ | ≤35mm | 16 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-377 | φ219-377 | 8‘’-14‘’ | ≤35mm | 13 r/min | 0.6~1.0MPa | 1500 L/min |

| OCP-426 | φ273-426 | 10‘’-16‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-457 | φ300-457 | 12‘’-18‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-508 | φ355-508 | 14‘’-20‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-560 | φ400-560 | 16‘’-22‘’ | ≤35mm | 12 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-610 | φ457-610 | 18‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-630 | φ480-630 | 20‘’-24‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-660 | φ508-660 | 20‘’-26‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-715 | φ560-715 | 22‘’-28‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 1800 L/min |

| OCP-762 | φ600-762 | 24‘’-30‘’ | ≤35mm | 11 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-830 | φ660-813 | 26‘’-32‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-914 | φ762-914 | 30‘’-36‘’ | ≤35mm | 10 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1066 | φ914-1066 | 36‘’-42‘’ | ≤35mm | 9 r/min | 0.6~1.0MPa | 2000 L/min |

| OCP-1230 | φ1066-1230 | 42‘’-48‘’ | ≤35mm | 8 r/min | 0.6~1.0MPa | 2000 L/min |

Note: Standard machine packaging including : 2 pcs cutter,2pcs of bevel tool +tools + operation manual

Fetures

1. Low axial and radial clearance light weight suitable for working at narrow and complicated site

2. Split frame design can separate to 2 half, easy to process when two end not open

3. This machine can process cold cutting and beveling simultaneously

4. With option for electric, Pneuamtic, Hydraulic ,CNC based on site condition

5. Tool feed automatically with Low noise, long life and stable performance

6. Cold working without Spark , Will not affect the pipe material

7. Can process different pipe material : Carbon steel, stainless steel , alloys etc

8. Explosion Proof, Simple structure makes easy to maintenance

Bevel Surface

Application

Widely used in the fields of petroleum, chemical, natural gas,power plant construction,bolier and nuclear power, pipeline etc.

Customer Site

Packaging