TMM-80R Turnable steel pate beveling machine for top and bottom bevel

Short Description:

GMMA-80R steel plate beveling machine with unique design which is turnable for both top beveling and bottom beveling process to avoid metal sheet over. Plate thickness 6–80mm, bevel angel 0-60 degree, Bevel width could reach max 70mm by market standard milling heads and inserts. Fully meet customer requirements with small bevel qty but double side beveling.

PRODUCT DESCRIPTION

This machine mainly utilizes millingprinciples. The cutting tool is used to cutand mill the metal sheet at the requiredangle to obtain the required groove forwelding. lt is a cold cutting process thatcan prevent any oxidation of the platesurface on the groove. Suitable for meta!materials such as carbon steel. stainlesssteel, aluminum alloy steel etc.Welddirectly after the groove, without theneed for additional deburring.Themachine can automatically walk alongthe edges of materials, and has theadvantages of simple operation, highefficiency, environmental protection, andno pollution.

Main Features

1.Machine walking along with plate edge for beveling cutting.

2. Universal wheels for machine easy moving and storage

3. Cold cutting to avoid any oxide layer by using market standard milling head and carbide inserts

4. High precision performance on bevel surface at R3.2-6..3

5. Wide working range, easy adjustable on clamping thickness and bevel angels

6. Unique design with reducer setting behind more safe

7. Available for multi bevel joint type like V/Y, X/K, U/J, L bevel and clad removal.

8. Beveling speed could be 0.4-1.2m/min

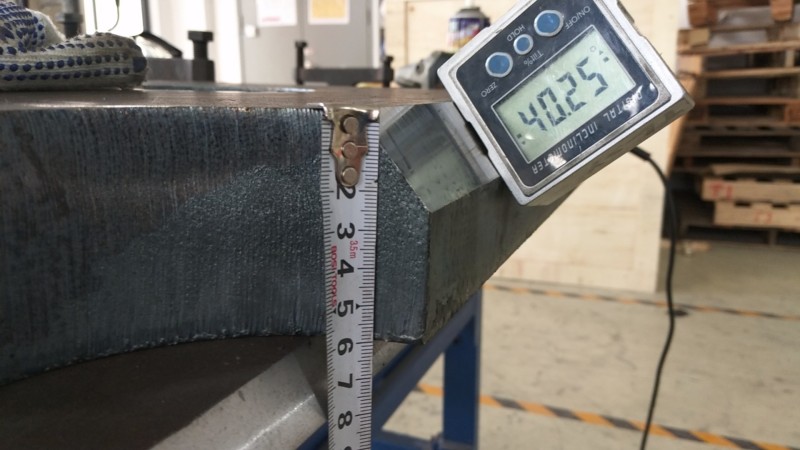

40.25 degree bevel

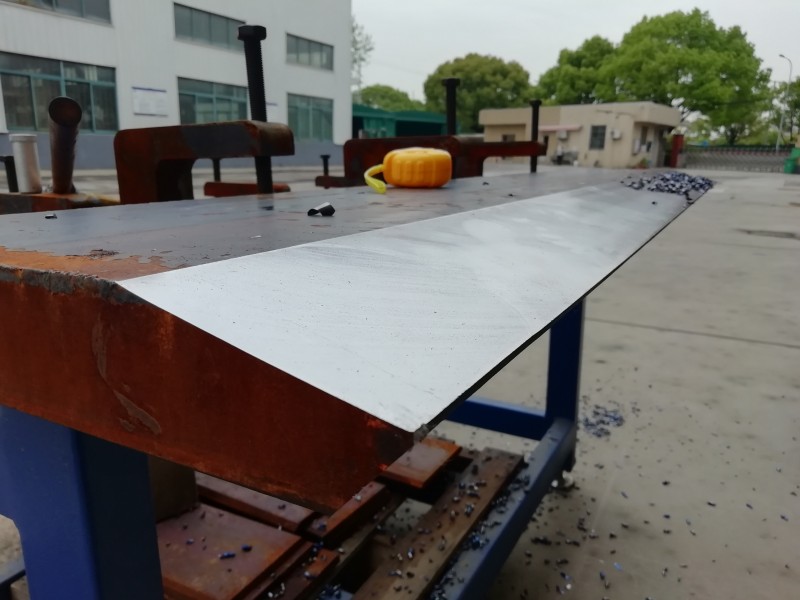

0 degree bevel

Surface finish R3.2-6.3

No oxidation on the surface of the bevel

PRODUCT SPECIFICATIONS

|

Models |

GMMA-80A |

GMMA-80R |

GMMA-100L |

GMMA-100U |

|

Power Suppy |

AC 380V 50HZ |

AC 380V 50HZ |

AC 380V 50HZ |

AC 380V 50HZ |

|

Total Power |

4920W |

4920W |

6520W |

6480W |

|

Spindle Speed |

500~1050r/min |

500-1050mm/min |

500-1050mm/min |

500-1050mm/min |

|

Feed Speed |

0~1500mm/min |

0~1500mm/min |

0~1500mm/min |

0~1500mm/min |

|

Clamp Thickness |

6~80mm |

6~80mm |

8~100mm |

8~100mm |

|

Clamp Width |

>80mm |

>80mm |

>100mm |

>100mm |

|

Clamp Length |

>300mm |

>300mm |

>300mm |

>300mm |

|

Bevel Angel |

0~60 degree |

0~±60 degree |

0~90 degree |

0~ -45 degree |

|

Singel Bevel width |

0-20mm |

0-20mm |

15-30mm |

15-30mm |

|

Bevel Width |

0-70mm |

0-70mm |

0-100mm |

0~ 45 mm |

|

Cutter Diameter |

Dia 80mm |

Dia 80mm |

Dia 100mm |

Dia 100mm |

|

Inserts QTY |

6 pcs |

6 pcs |

7 pcs/9pcs |

7 pcs |

|

Worktable Height |

700-760mm |

790-810mm |

810-870mm |

810-870mm |

|

Worktable Size |

800*800mm |

1200*800mm |

1200*1200mm |

1200*1200mm |

|

Clamping Way |

Auto Clamping |

Auto Clamping |

Auto Clamping |

Auto Clamping |

|

Machine N.Weight |

245 kgs |

310 kgs |

420 kgs |

430 kgs |

|

Machine G Weight |

280 kgs |

380 kgs |

480 kgs |

480 kgs |

Successful Project

V bevel

U/J bevel

Machine shipment

Machine strapped on pallets and wrapped in wooden case against international Air / Sea Shipment