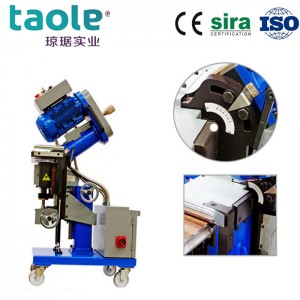

GMMA-60S self propelled metal edge chamfering machine

Short Description:

GMMA Plate edge beveling milling machines provide high efficiency and precisious performance on welding bevel & joint processing. With wide working range of plate thickness 4-100mm, bevel angel 0-90 degree, and customized machines for option. Advatages of low cost, low noise and higher quality.

GMMA-60S self propelled metal edge chamfering machine

Products Introduction

GMMA-60S plate edge milling machine with working range of Clamp thickness 6-60mm, bevel angel 10-60 degree adjustable on metal edge beveling for weld preparation. GMMA series with high precious could reach Ra 3.2-6.3.

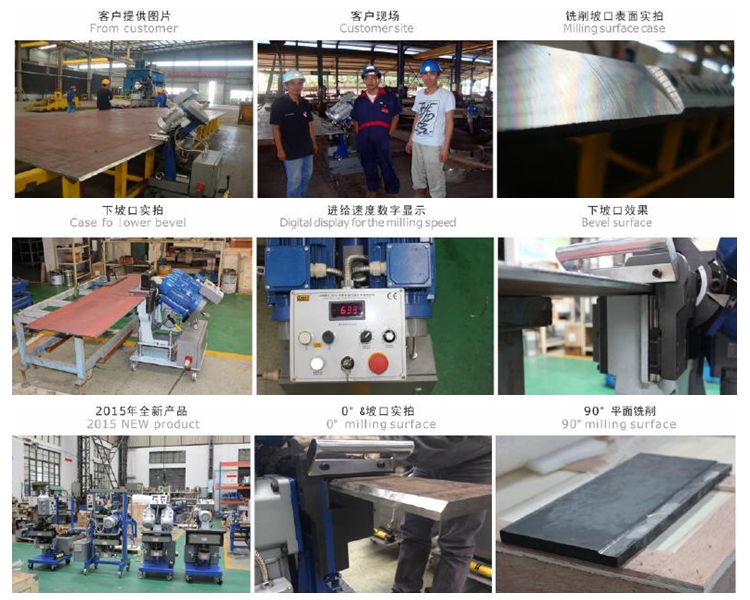

There are 2 processing Way:

Model 1: Cutter catch the steel and lead into the machine to complete job while processing small steel plates.

Model 2: Machine will travel along the edge of steel and complete job while processing large steel plates.

Specifications

| Model No. | GMMA-60S plate edge milling machine |

| Power Supply | AC 380V 50HZ |

| Total Power | 3400W |

| Spindle Speed | 1050r/min |

| Feed Speed | 0-1500mm/min |

| Clamp Thickness | 6-60mm |

| Clamp Width | >80mm |

| Process Length | >300mm |

| Bevel angel | 0-60 degree adjustable |

| Single Bevel Width | 10-20mm |

| Bevel Width | 0-45mm |

| Cutter Plate | 63mm |

| Cutter QTY | 6PCS |

| Worktable Height | 700-760mm |

| Travel Space | 800*800mm |

| Weight | N.W 200KGS G.W 255KGS |

| Packaging Size | 800*690*1140mm |

Note: Standard Machine including 1pc cutter head + 2 set of Inserts + Tools in case + Manual Operation

Fetures

1. Available for metal plate Carbon steel,stainless steel, aluminium etc

2. Can process “K”,”V”,”X”,”Y” vary type of bevel joint

3. Milling Type with High Previous can reach Ra 3.2-6.3 for surface

4.Cold Cutting, energy saving and Low Noise, More safe and environmental

5. Wide working range with Clamp thickness 6-60mm and bevel angel 10-60 degree adjustable

6. Easy Operation and high efficiency

Bevel Surface

Application

Widely used in aerospace, petrochemical industry, pressure vessel, shipbuilding, metallurgy and unloading processing factory welding manufacturing field.

Exhibition

Packaging