TMM-100K Double Sided beveling machine for metal sheet

Short Description:

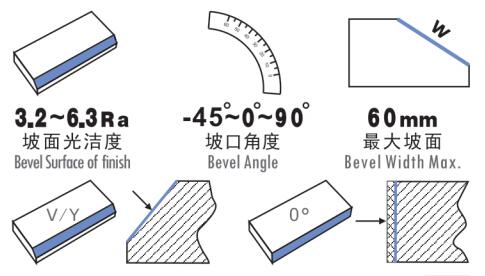

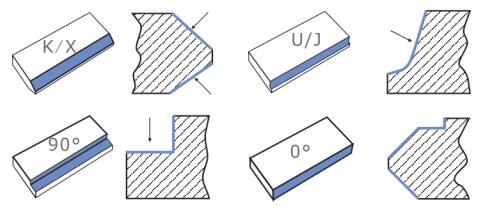

Double Sided plate beveling machine are highly required for heavy duty plate welding industry. Specially for K/X type bevel joint against welding. GMMA-100K beveling machine available for plate thickness 6-100mm. It can do top bevel and bottom bevel at same cutting to reach a high efficiency which saving time and cost.

Introduction of GMMA-100K Double Sided beveling machine for metal sheet

Metal sheet edge beveling machine mainly to do bevel cutting or clad removal / clad stripping on steel plates material like mild steel, stainless steel, aluminum steel,alloy titanium,hardox,duplex etc. GMMA-100K double sided beveling machine with 2 milling heads to process both top bevel and bottom bevel at same cut for plate thickness from 6mm to 100mm. It is considered two beveling machine working at same time for a X or K type bevel joint which is high efficiency and helps a lot for saving time and cost.

GMMA-100K beveling machine available for multi bevel joint

|

|

Parameters of GMMA-100K Double Sided beveling machine for metal sheet

| Models | GMMA-100K Double sided beveling machine |

| Power Suppy | AC 380V 50HZ |

| Total Power | 6480W |

| Spindle Speed | 500~1050r/min |

| Feed Speed | 0~1500mm/min |

| Clamp Thickness | 6~100mm |

| Clamp Width | ≥100mm |

| Clamp Length | ≥400mm |

| Bevel Angel | Top 0~90 ° and Down 0~-45° |

| Singel Bevel width | 0-20mm |

| Bevel Width | Top 0~60mm and Down 0~45mm |

| Cutter Diameter | 2 * Dia 63mm |

| Inserts QTY | 2 * 6 pcs |

| Worktable Height | 810-870m'm |

| Suggest Table Height | 830mm |

| Worktable Size | 800*800mm |

| Clamping Way | Auto Clamping |

| Wheel Size | 4 Inch Heavy duty |

| Machine Height Adjust | Handwheel |

| Machine N.Weight | 395 kgs |

| Machine G Weight | 460 kgs |

| Wooden Case Size | 950*1180*1430mm |

GMMA-100K plate beveling machine standard packing list and wooden case packaging for reference

|

|

Advantages for TAOLE GMMA-100K double sided beveling machine

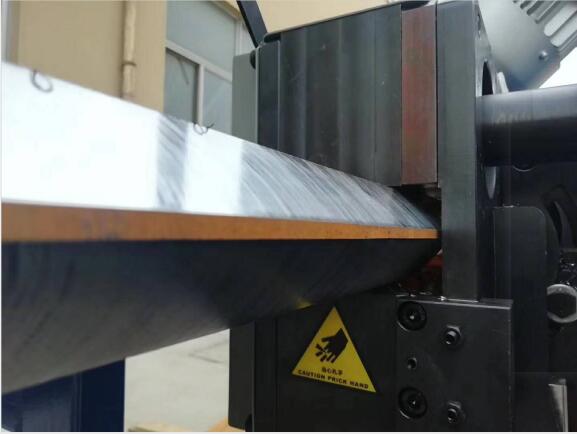

1) Automatic walking type beveling machine will walk along with plate edge for bevel cutting

2) Beveling machines with universal wheels for easy moving and storage

3) Cold cutting to aovid any oxide layer by using milling head and inserts for higher performance on surface Ra 3.2-6.3

It can do welding directly after bevel cutting. Milling inserts are market standard.

4) Wide working range for plate clamping thickness and bevel angels adjustable.

5) Unique design with reducer setting behand more safe.

6) Available for multi bevel joint type and easy operation.

7) High efficiency beveling speed reach 0.4~1.2 meters per min.

8) Automatic Clamping system and hand wheel setting for slight adjustment.

|

|

Application for GMMA-100K Double sided beveling machine.

Plate beveling machine are widely applicated for all welding industry. Such as

1) Steel Construction 2) Shipbuilding Industry 3) Pressure Vessels 4) Welding Manufacturing

5) Construction Machinery & Metallurgy

|

|

Surface Performace after bevel cutting by GMMA-100K double sided beveling machine

K/ X type bevel joint is main function for GMMA-100K model

|

|

|

|