TMM-VX4000 CNC Edge Milling Machine

Short Description:

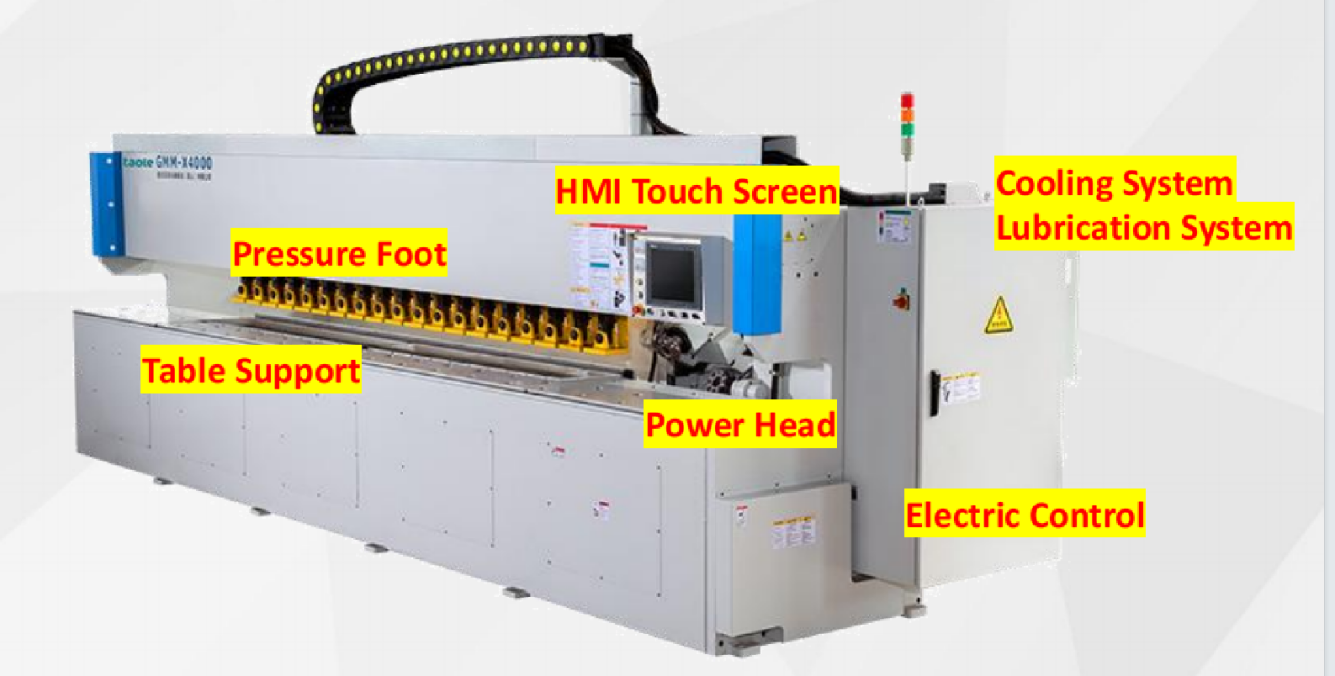

Metal Edge Milling Machine is a Special Purpose Machine developed for edge milling for sheet metal upto 100mm thick with carbide cutters. The machine is capable of metal edge milling (cold bevel cutting) operation. Also milling head will be given with a tilting facility for carrying bevelling operation at any required angle. This CNC edge milling machine comes with HMI interface with fully aotumatic system for easy operation to achieve a high precision bevel performance.

FEATURES AT A GLANCE

TMM-V/X4000 CNC edge milling machine is a type of milling machine to process bevel cutting on metal sheet. It is an advanced version of the traditional edge milling machine, with increased precision and accuracy. The CNC technology with PLC system allows machine to perform complex cuts and shapes with high levels of consistency and repeatability. The machine can be programmed to mill the edges of the work piece to the desired shape and dimensions. CNC edge milling machines are often used in metalworking, manufacturing industries where high precision and accuracy are required, such as aerospace, automotive, Pressure Vessel, Boiler, Shipbuilding,Power plant etc.

Features and advantages

1.More Safe: work process without operator participation,control box at 24 Voltage.

2.More Simple: HMI Interface

3.More Environmental:Cold cutting and milling process without pollution

4.More Efficient: Processing Speed of 0~2000mm/min

5.Higher Accuracy: Angel ±0.5 degree,Straightness ±0.5mm

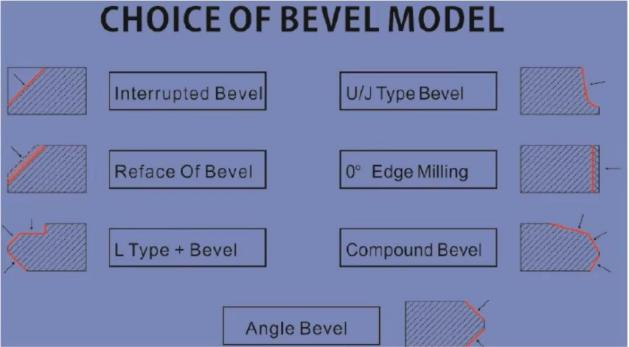

6.Cold cutting, no oxidation and deformation of the surface 7.Processing Data storage function, call the program at any time 8.Touch screw input data, one button to start beveling operation 9.Optional bevel joint diversification, Remote system upgrade available

10.Optional material processing records. Parameter setting without manual calculation

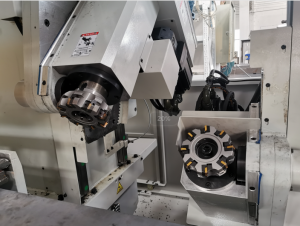

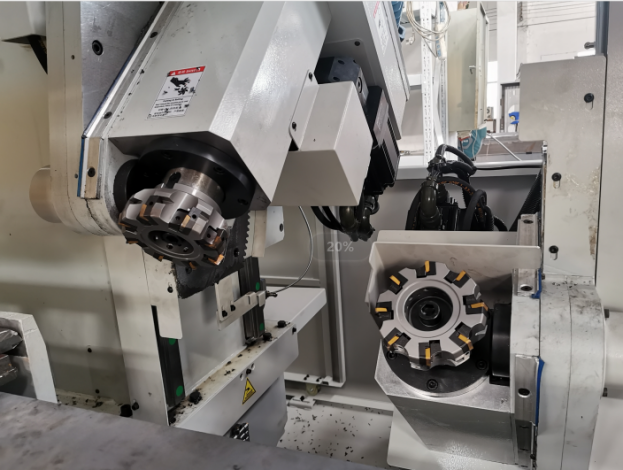

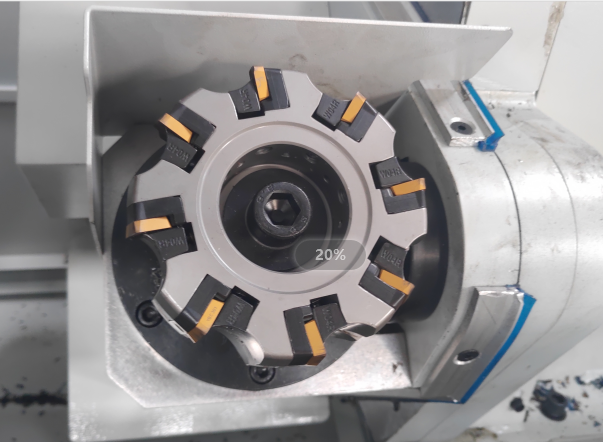

Detailed Images

PRODUCT SPECIFICATIONS

| Model Name | TMM-6000 V Single Head

TMM-6000 X Double Heads |

GMM-X4000 |

| V for Single Head | X for Double head | |

| Max Machine Stroke Length | 6000mm | 4000mm |

| Plate Thickness Range | 6-80mm | 8-80mm |

| Bevel Angel | Top:0-85 degree + L 90 degree

Bottom: 0-60 degree |

Top Bevel: 0-85 degree, |

| Buttom Bevel: 0-60 Degree | ||

| Processing Speed | 0-2000mm/min(Auto Setting) | 0-1800mm/min(Auto Setting) |

| Head Spindle | Independent Spindle for Each Head 7.5KW*1 PCS

Single head or double heads each 7.5KW |

Independent Spindle for Each Head 5.5KW*1 PC Single Head or Double Head each at 5.5KW |

| Cutter Head | φ125mm | φ125mm |

| Pressure Foot QTY | 14 PCS | 14 PCS |

| Pressure Foot Move Back and Forth | Automatically Position | Automatically Position |

| Table Move Back and Forth | Manual Position(Digital Display) | Manual Position(Digital Display) |

| Small Metal Operation | Right Start End 2000mm(150x150mm) | Right Start End 2000mm(150x150mm) |

| Safety Guard | Semi-enclosed sheet metal shield Optional Safety System | Semi-enclosed sheet metal shield Optional Safety System |

| Hydraulic Unit | 7Mpa | 7Mpa |

| Total Power & Machine Weight | Approx 15-18KW and 6.5-7.5 Ton | Approx 26KW and 10.5 Ton |

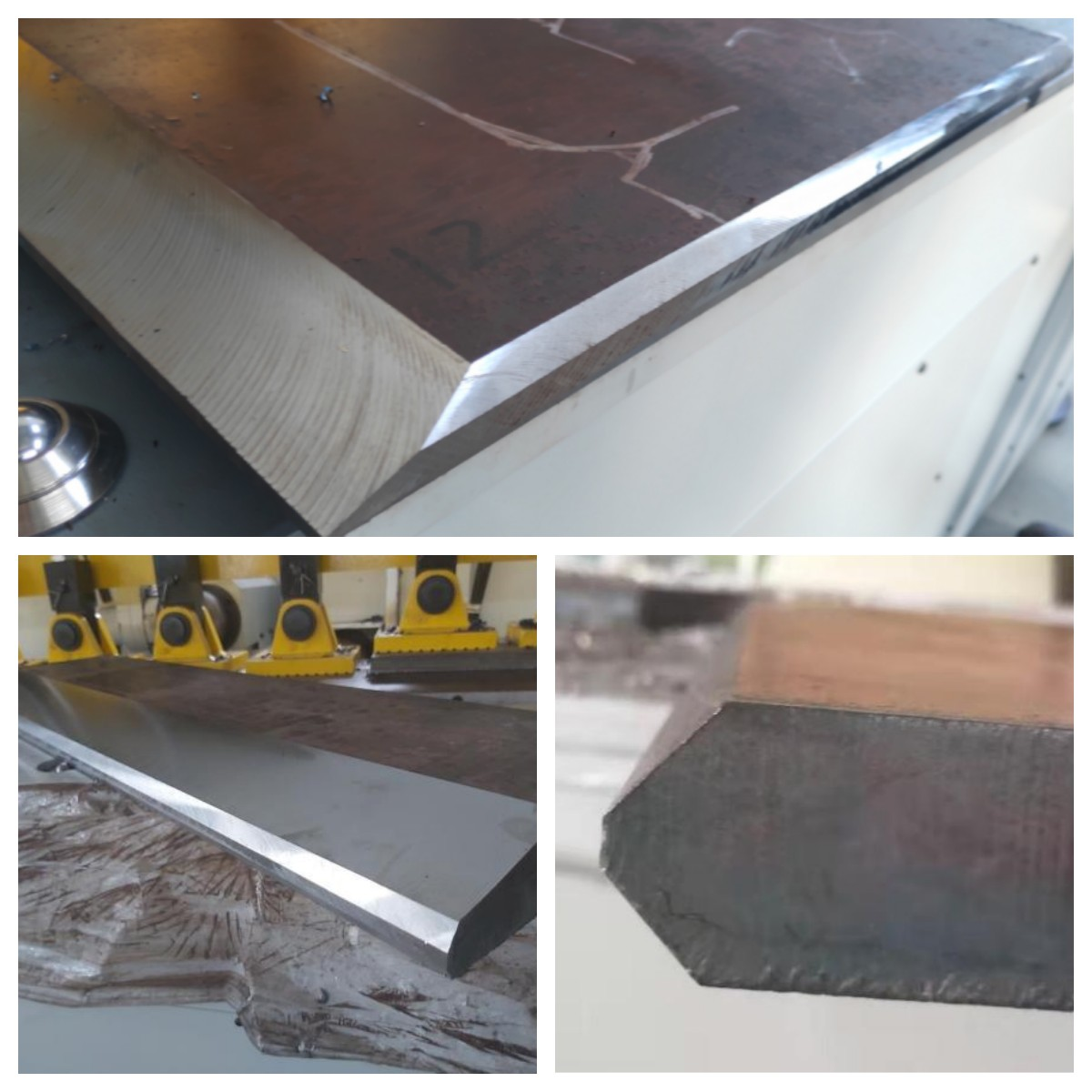

Processing performance

Machine Packing

Successful Project